5 Automation Trends Transforming Manufacturing

Automation in manufacturing is no longer about just improving efficiency—it’s about building smarter, more adaptable systems that can respond to real-time challenges. To understand the trends driving this transformation, we spoke with five leading industry experts.

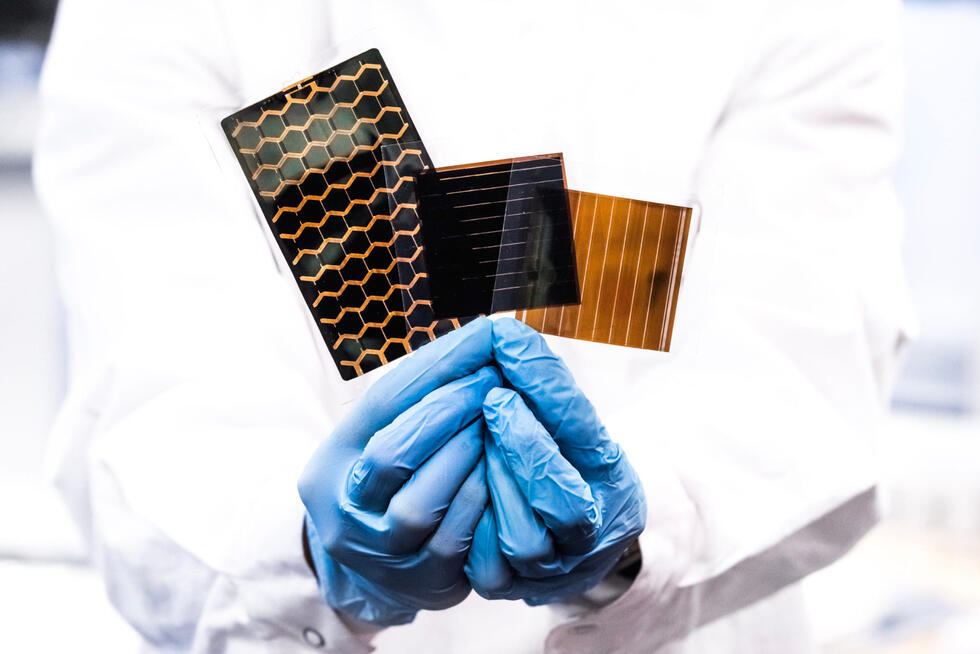

Trend 1: Artificial Intelligence Enables End-to-end Automation

In the past, automation used to focus on specific tasks, leading to a patchwork of isolated solutions. Artificial Intelligence (AI) now enables companies to automate entire workflows. AI-powered automation will be pushing the limits, allowing to bridge the existing gaps.

Pascal Bornet, an award-winning AI expert and best-selling author, highlights how automation has evolved to address scaling issues:

"Previously, organizations could successfully implement automation pilots but struggled to scale them enterprise-wide. Today, we’re seeing the emergence of true end-to-end automation with AI at its core, creating self-reinforcing ecosystems of intelligence."

AI-driven automation is helping manufacturers forecast demand more accurately, leading to more stable and efficient operations. Bornet emphasizes the importance of real-time data flow between systems:

"I've worked with companies that now connect real-time production data with supply chain systems, quality control, and even customer feedback loops," he explains. "This connectivity allows automation to optimize across the entire value chain rather than just within functional areas."

Trend 2: Interconnected Systems Are Outpacing Real-time Challenges

The industrial internet of things (IIoT) and cloud-based automation platforms open up the possibility of interconnecting the production line, increasing the agility of the manufacturing process. By breaking down silos and improving data flow, companies are able to respond more quickly to market shifts and supply chain challenges.

According to Meaghan Ziemba, a technical writer and podcaster on manufacturing, automation has shifted from being reactive to proactive:

"Five years ago, automation was about keeping up—now, it's about outpacing challenges before they hit," she explains. "Smarter automation is addressing labor shortages and reducing bottlenecks where skilled hands were once the only answer."

Ziemba highlights how interconnected systems are not only reducing downtime but are also improving quality management:

"In food processing, for example, seamless data sharing from raw ingredient intake to final packaging means fewer recalls and less downtime," she says. "If your systems aren't talking to each other, consider yourself already behind."

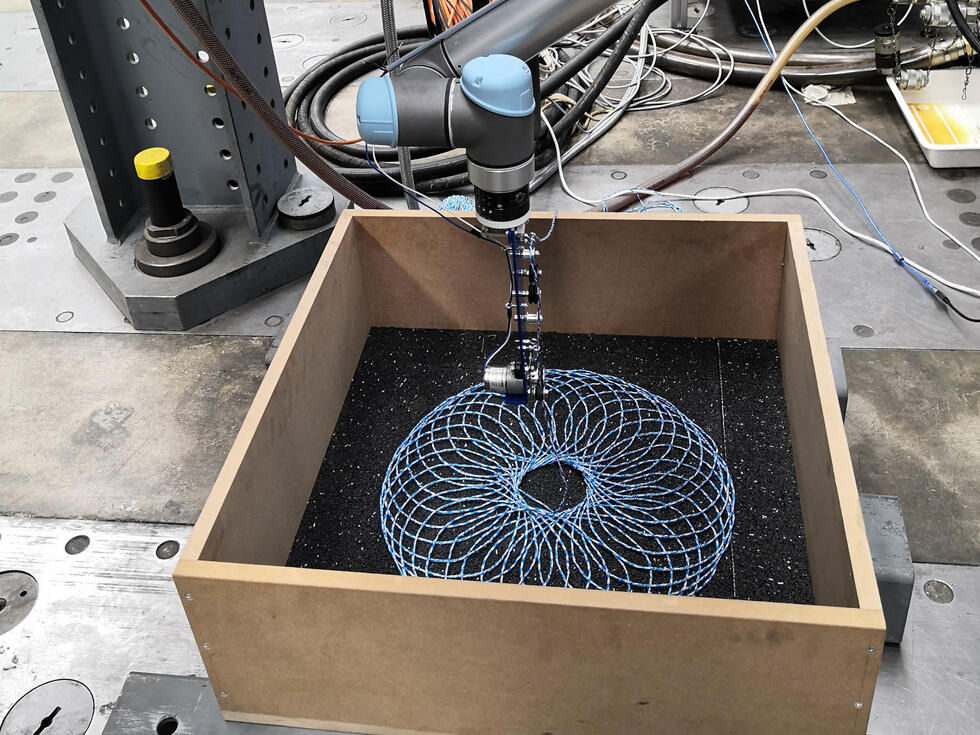

Trend 3: AI-Driven Robotics Are Reshaping Internal Logistics

Robots are no longer confined to assembly lines—they’re now playing a key role in warehouse management and internal logistics. While automated guided vehicles (AGVs) are depending on fixed tracks, autonomous mobile robots (AMRs) are able to move more freely and to avoid obstacles.

Nandan Mullakara, a strategic advisor, author, and podcaster on AI and automation, highlights the growing importance of autonomous systems like AMRs:

"Agentic automation, robotics, and digital twins will transform industries, moving beyond the blue and white collar jobs of today."

AI-driven Robotics make internal logistics more flexible, optimizing warehouse management and reducing manual material handling. Mullakara underlines that mastering these technologies demands a whole set of different skills:

"These innovations will require a fusion of creative problem-solving, business acumen, and technical expertise."

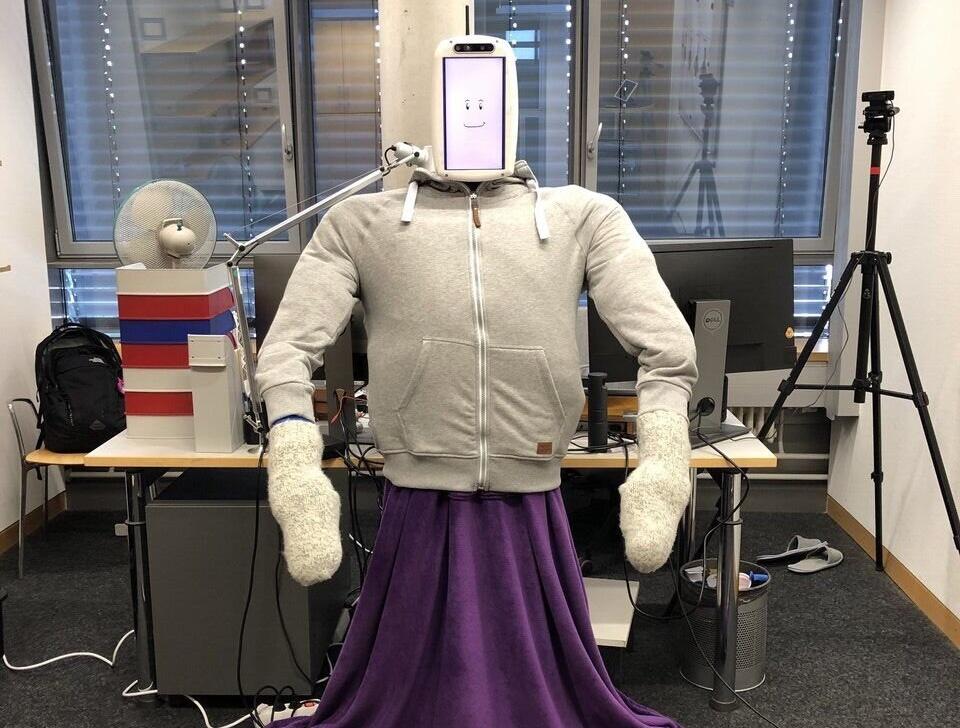

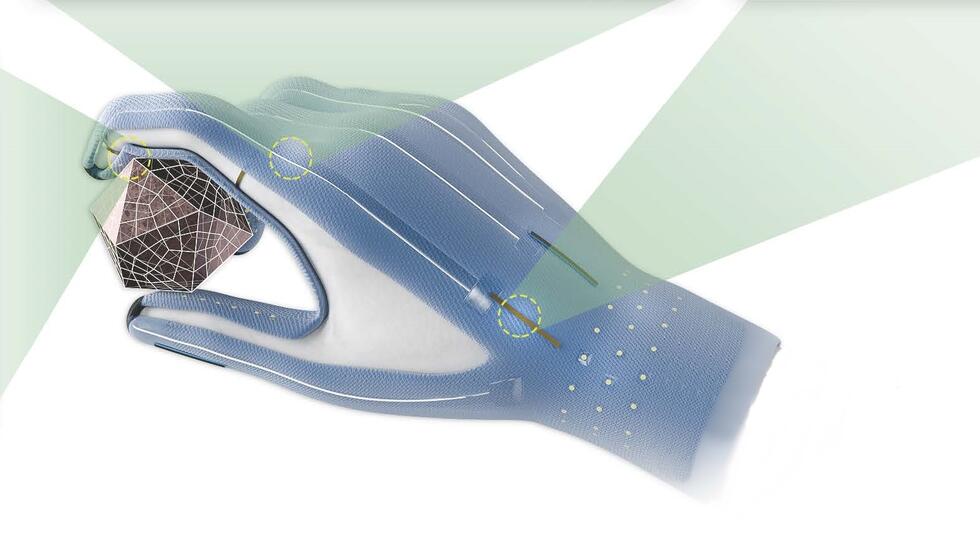

Trend 4: Extended Reality (XR) is Changing Workforce Training

As manufacturing becomes more automated, workforce training needs to evolve. Extended reality (XR)—including augmented and virtual reality—is providing new ways to train employees in real-time production environments. This allows manufacturers to reduce training time, improve knowledge retention, and equip workers with the skills needed to operate in complex automated environments.

Kieran Gilmurray, a globally recognized authority on AI and automation, highlights the potential of XR:

"XR will reshape workforce training and enable remote troubleshooting environments," he explains. "These advances lead to a shift from traditional manufacturing roles to those requiring digital literacy, data analysis, and automation management expertise."

Trend 5: Workforce Upskilling Will Be Critical For The Next Automation Wave

As automation becomes more advanced, manufacturers will need to invest in upskilling their workforce to remain competitive. AI-driven automation will require workers to shift from routine operations at the production line to more strategic roles.

Peggy Smedley, a tech journalist and sustainability influencer, emphasizes the importance of aligning automation with human capability:

"Automation is becoming more intelligent with the help of AI—and this will undoubtedly have an impact on workforce development and skill requirements."

Manufacturers that invest in training and AI literacy will not only avoid displacement—they’ll create a more innovative and adaptable workforce. Smedley emphasizes that this means continuous development:

"We must ensure people are the driving force for technology and that digital transformation is viewed as a journey, not a destination."