SHORT NEWS

Knitted roads

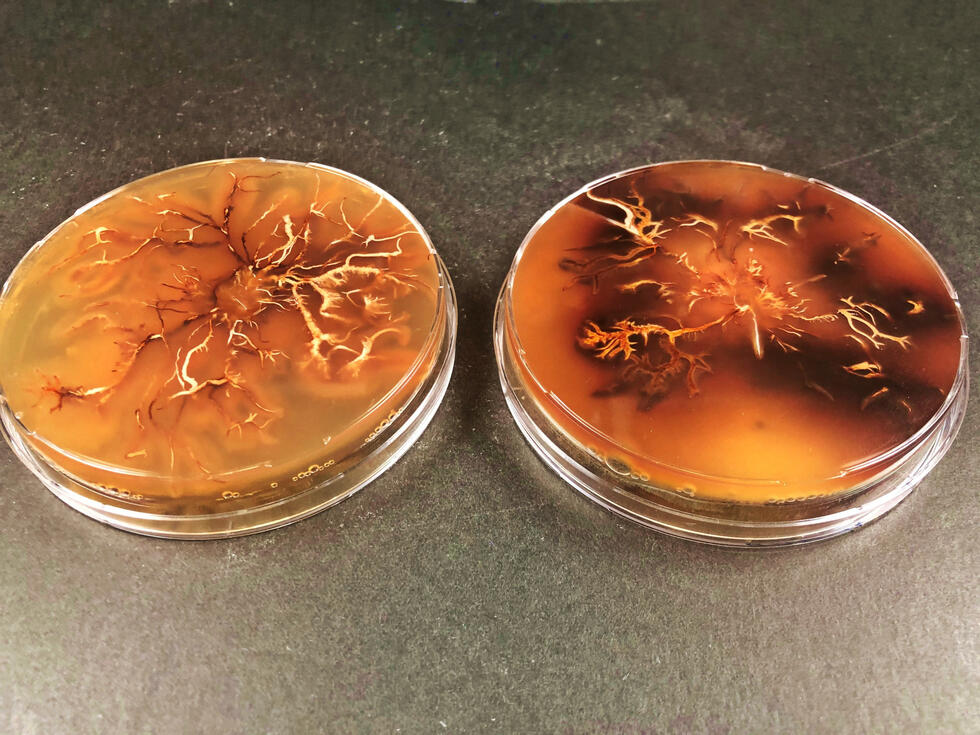

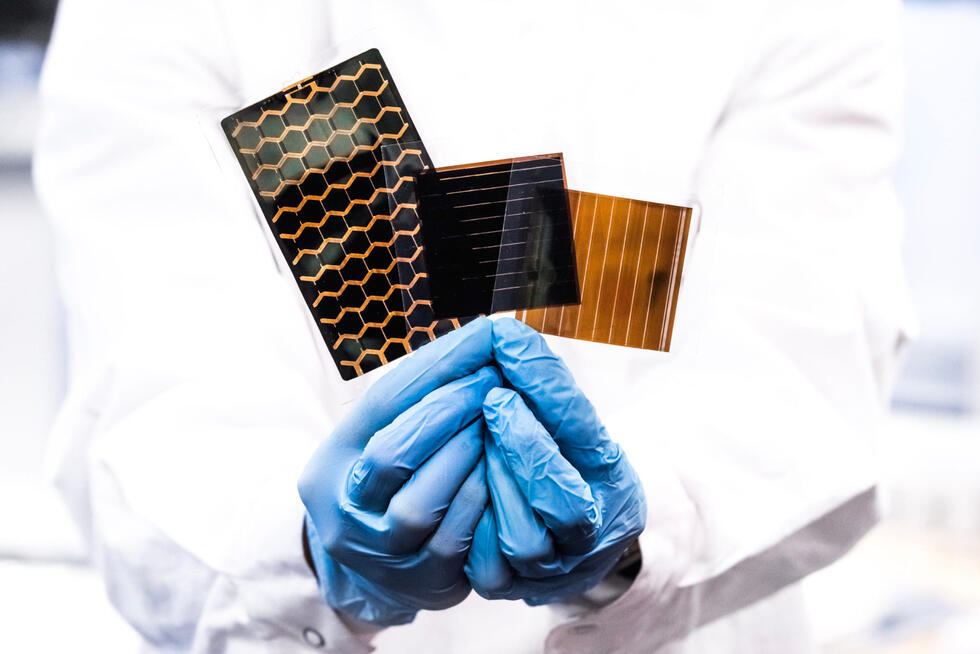

Road pavements require bitumen as a binder. But its production has many disadvantages. Empa researchers are now experimenting with string, which holds gravel together without the need for concrete - and is also more flexible, more permeable to rainwater and more environmentally friendly.

Bitumen, the substance that holds gravel together in road pavements, has many disadvantages: Because it is extracted from crude oil, its production produces gases that are harmful to the environment. Bitumen also makes road surfaces susceptible to cracking and deformation and impervious to rainwater. And what's more, road surfaces with bitumen are not reusable.

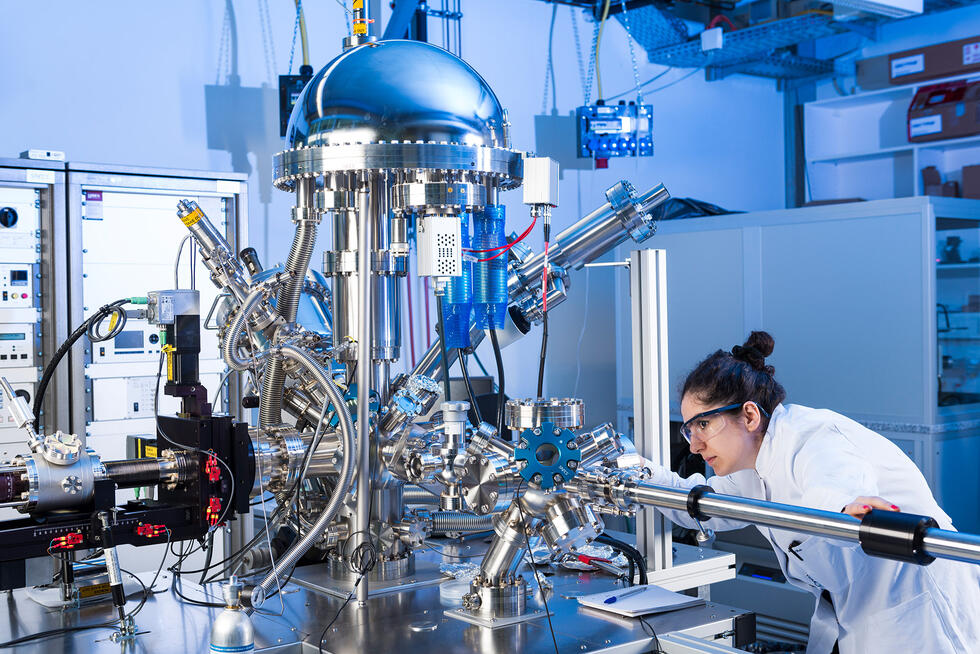

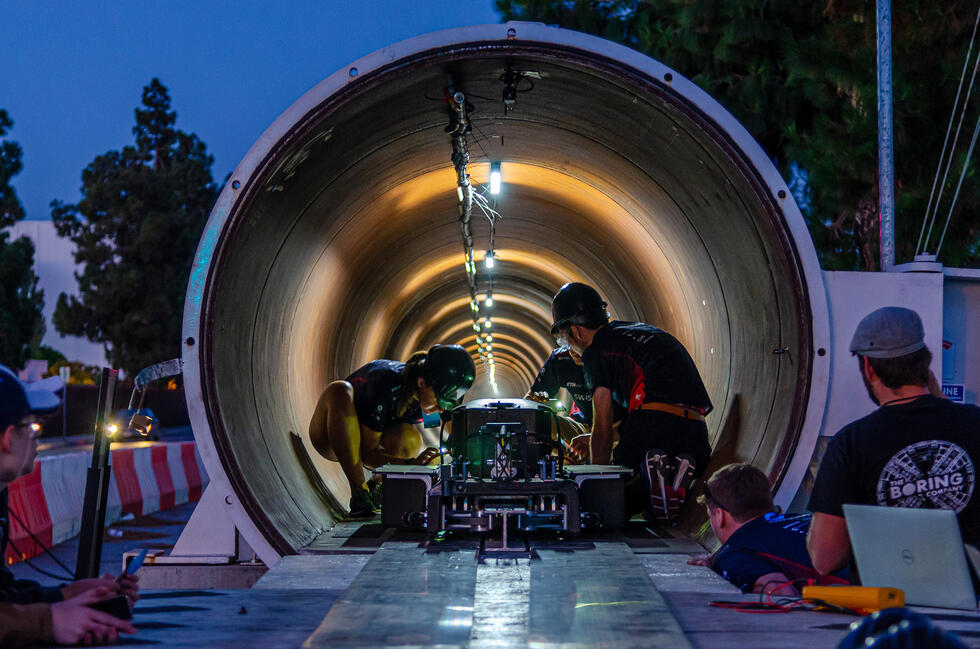

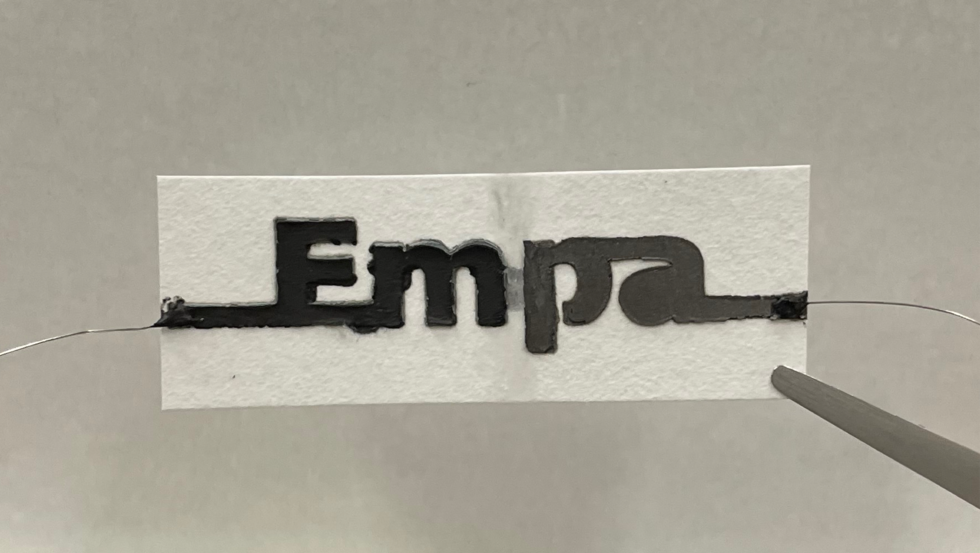

The idea of using twine as a binder was born out of art, the "Rock Print Pavilion" art project at ETH Zurich: sturdy columns of gravel held together with packing cord. Laboratory tests showed that gravel columns with a height of 80 cm and a diameter of 33 cm can withstand a pressure of 200 kN, which corresponds to a load of 20 tons. In the art project, a robot laid the cord.

The package withstands pressure

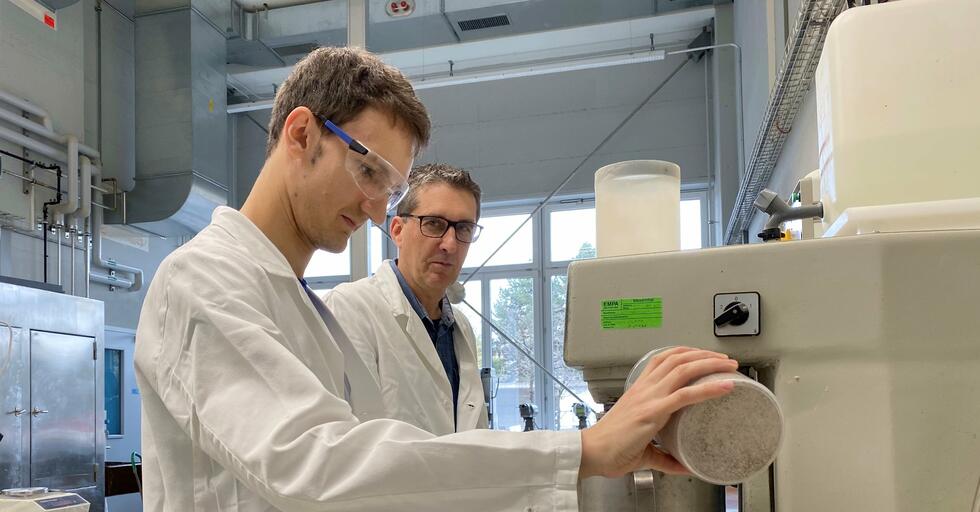

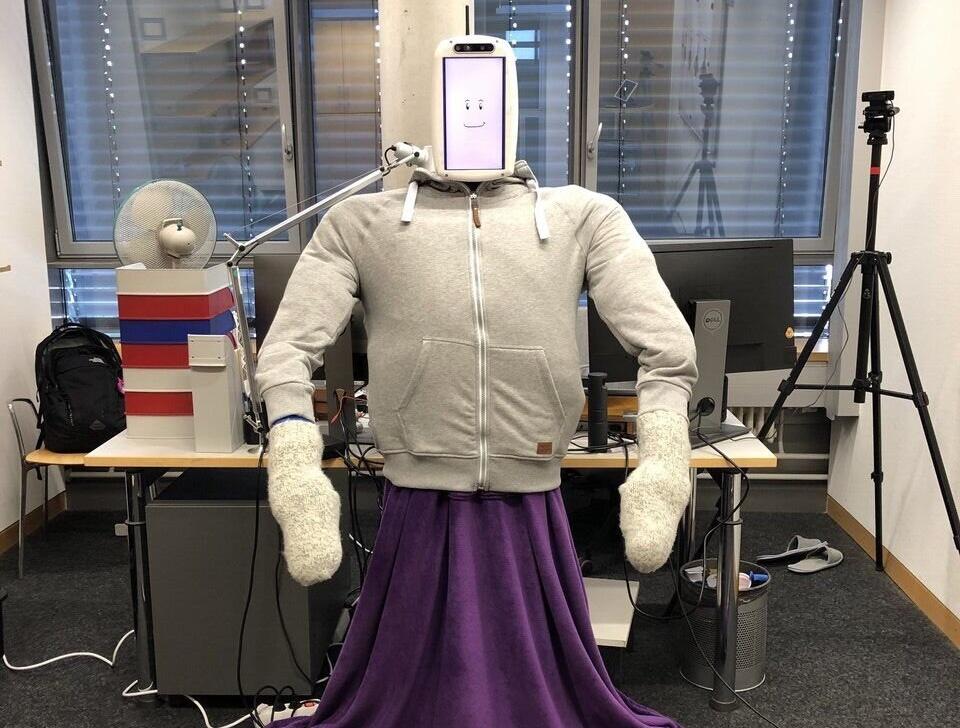

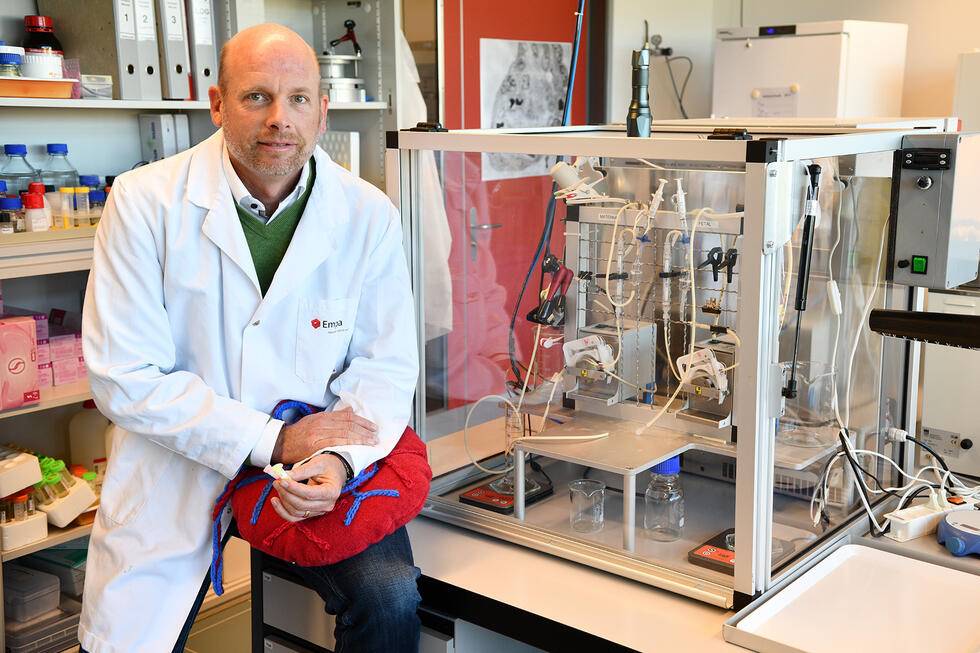

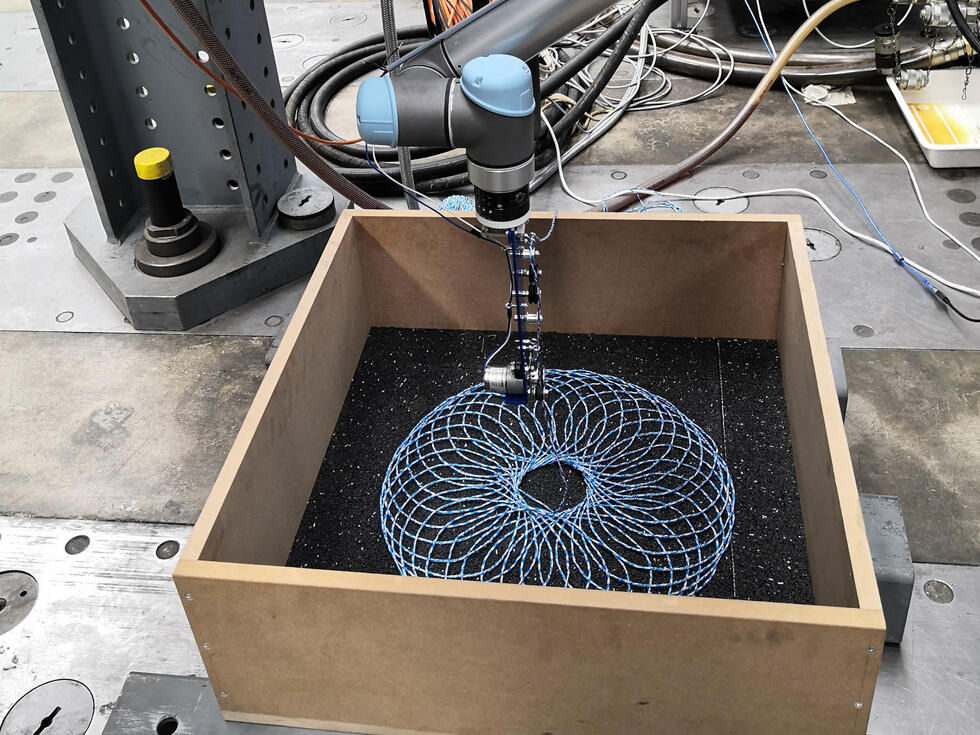

In the experiments currently underway at Empa, a robot arm is responsible for laying out the string: it places it in a programmed pattern on the layers of ballast stacked on top of each other. For the mechanical tests, five of these layers of gravel and string are placed on top of each other in a rubber-bottomed test box.

The gravel string package is then loaded with a turntable and pressure. This load test shows: By wrapping the individual pebbles with the thread, the package can withstand a pressure of 5 kN - half a ton - without the stones moving much.