SHORT NEWS

ETH researchers produce fuel from sunlight and air

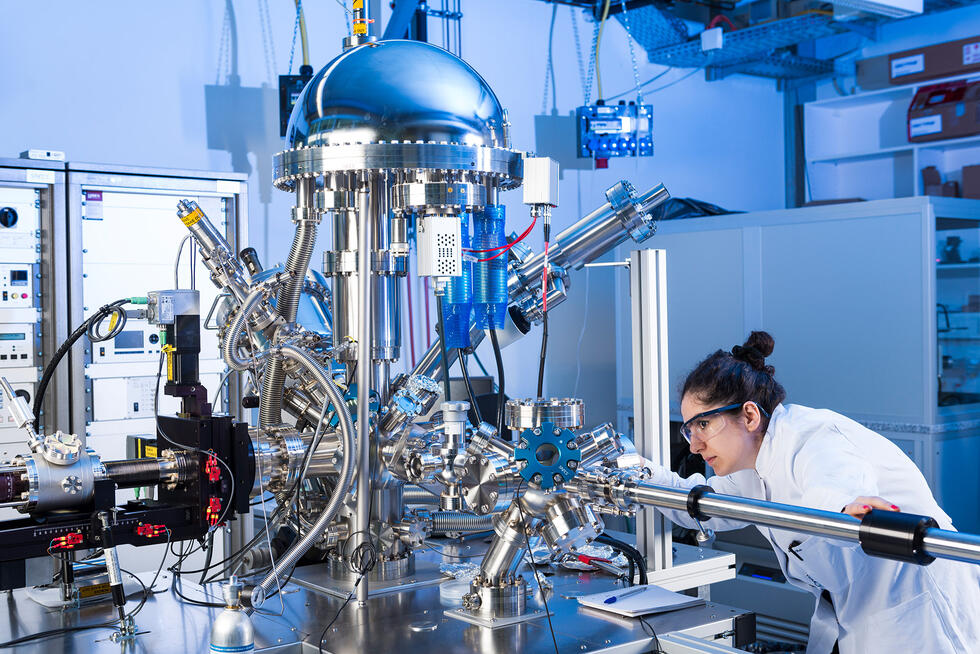

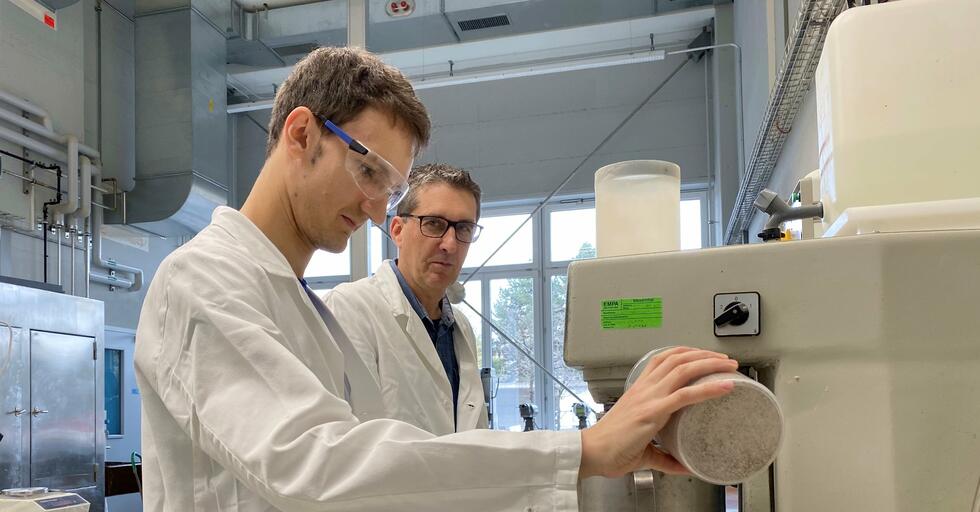

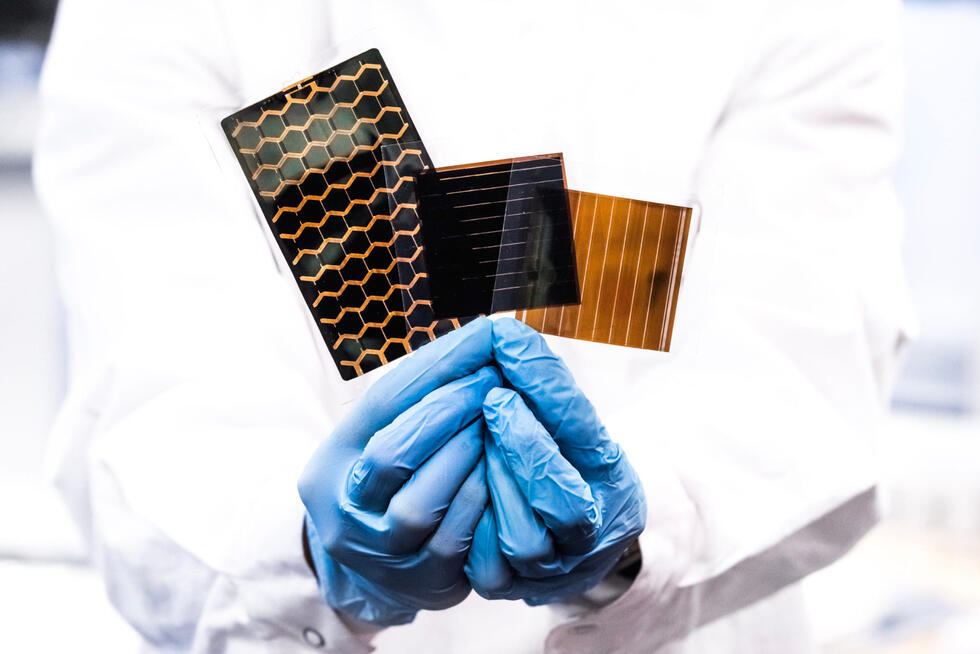

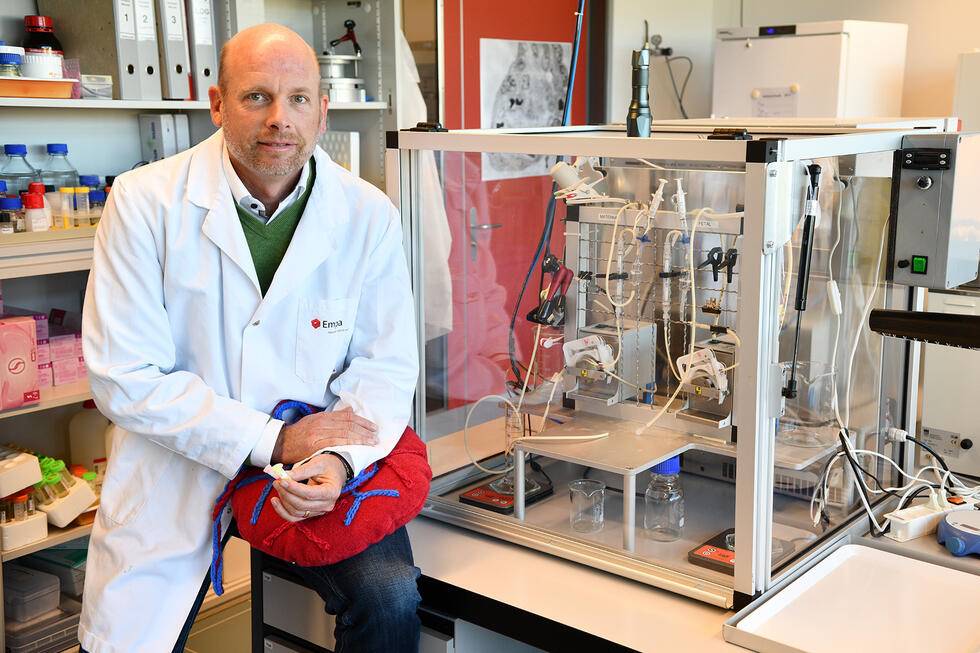

Researchers at the Swiss Federal Institute of Technology in Zurich (ETH) have achieved a world première: They have developed a technology that produces carbon-neutral fuels using only sunlight and air. The solar refinery is already operating under real-life conditions.

Carbon-neutral petrol, diesel, or kerosene made from air and sunlight: Something that in this age of climate debate sounds like a dream of humankind has become reality at the ETH Zurich. For the first time ever, ETH researchers have presented the entire thermochemical process chain for the production of solar fuels under real-life conditions.

The new mini solar refinery is located on the roof of the ETH Machinery Laboratory in the center of Zurich. The refinery currently produces methanol – one tenth of liter a day. However, it is capable of synthesizing a wide range of the fossil fuels commonly used today.

The fuels produced are carbon-neutral: During combustion, the same amount of CO2 is emitted as was extracted from the ambient air during the production process.

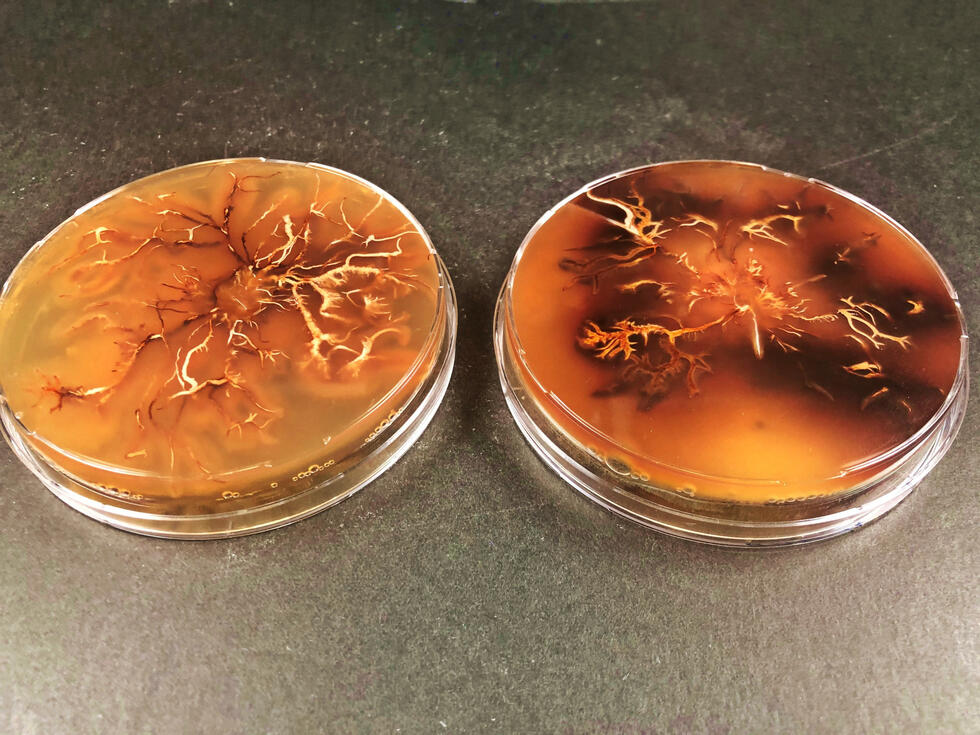

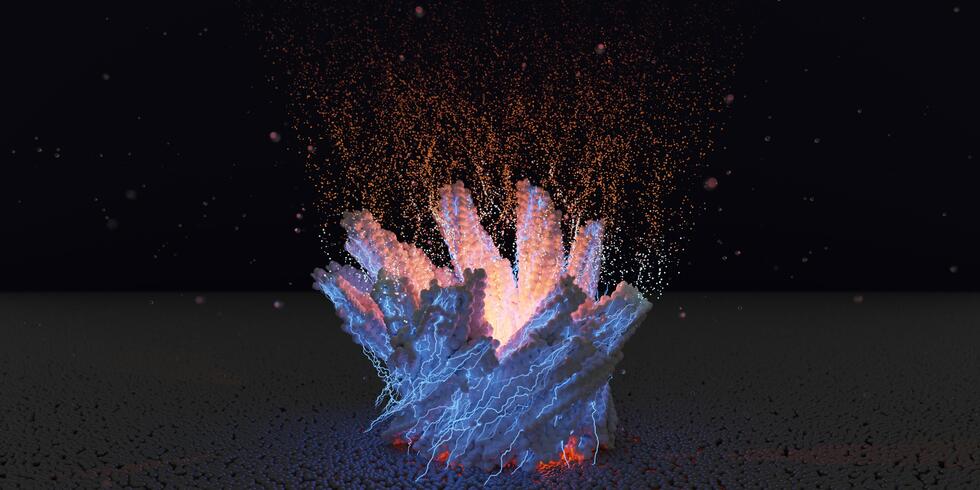

The key component and the actual innovation are two solar reactors that are heated to 1500 degrees Celsius using sunlight focused by a parabolic mirror. They convert carbon dioxide and water into syngas, a mixture of hydrogen and carbon monoxide. In an additional step, syngas is processed into various hydrocarbons, the most commonly used fuels today.

The CO2 and water that are initially required are extracted directly from the ambient air. This technology was also developed by the ETH Zurich. The waste heat from the solar reactor can be used as an energy source for the first reaction stage.

Successful under real-life conditions

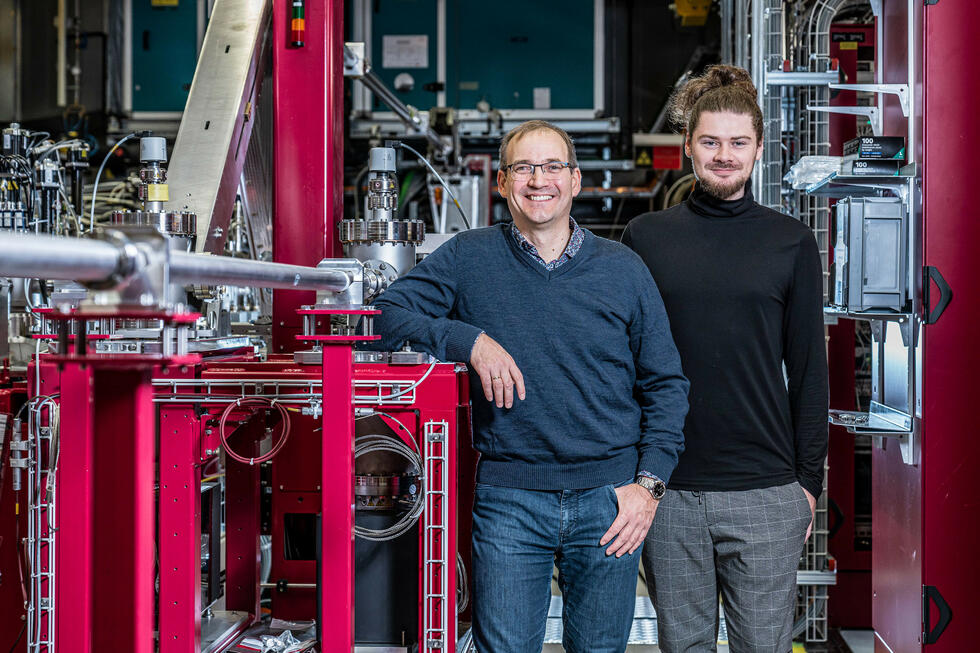

“With this system, we are demonstrating that the production of sustainable fuel using sunlight and air also works under real-life conditions,” says Aldo Steinfeld, Professor of Renewable Energy Carriers at ETH Zurich.

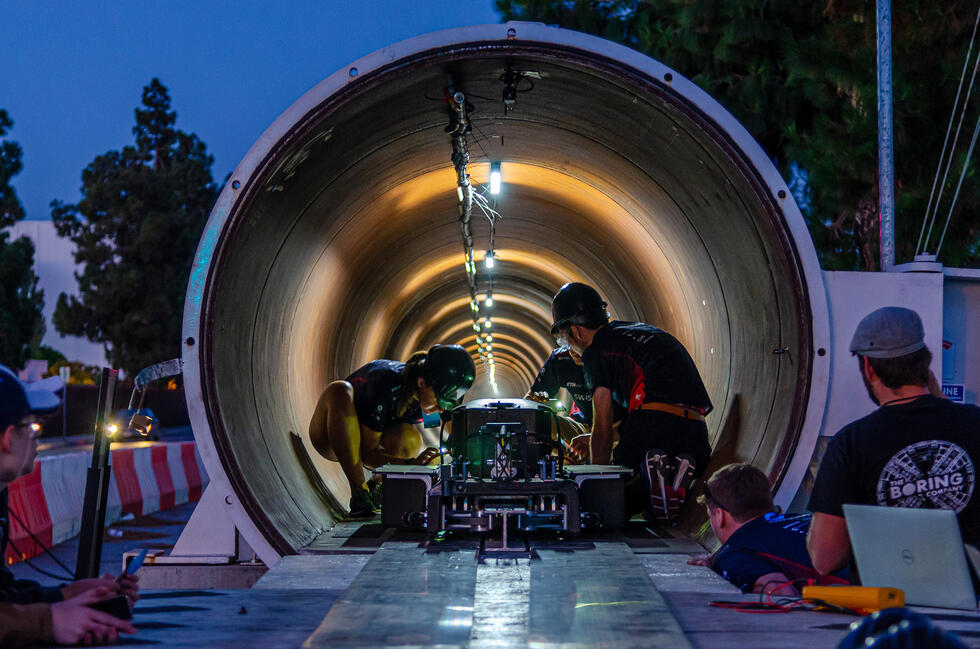

Aldo Steinfeld, who developed the technology together with his research team, also presented a second system to the public in Madrid. The ETH system in Spain produces kerosene and is considerably larger than the mini refinery in Zurich. With its solar tower and a ground-mounted mirror array, it illustrates the path to commercial dimensions.

Philipp Furler, a scientific assistant at the ETH Zurich, revealed that this could be achieved as early as 2025. As the CTO of the ETH spin-off company Synhelion, he is developing the existing research system into an industrial production facility.

The challenge is to increase the size of the plant from 200 kilowatts to 40 megawatts. And the sunlight must be exploited more efficiently in order to produce fuels in an economically viable manner. “The parabolic mirrors are the main cost factor,” Philipp Furler explains. “This means that we have get by with fewer mirrors.” The young researcher is optimistic: The technological path towards achieving higher efficiency is already clear.

Of interest to the aviation sector

In six years, if everything goes according to plan, Synhelion will commission its first commercial facility with a production capacity of 10 million liters of solar fuel per year.

Philipp Furler views airlines as the prime customers. “The aviation industry has no alternatives to fossil fuels,” he explains. Batteries are simply too heavy for aircraft. In the long term, Philipp Furler estimates that the cost of solar kerosene will stabilize at approximately one to two euro per liter. By comparison, one liter of fossil kerosene currently costs about 50 cents before tax.

A one square kilometer solar plant could produce 20,000 liters of kerosene a day. According to the ETH researchers, the kerosene demand of the entire aviation sector could thus be covered by a plant covering the area of Switzerland or one third of the Mojave Desert in California.

However, Switzerland is an unsuitable location for an industrial facility. What is required are large open spaces as well as intense and constant sunlight. This would not necessarily have to be deserts – favorable conditions can already be found in South Europe.