SHORT NEWS

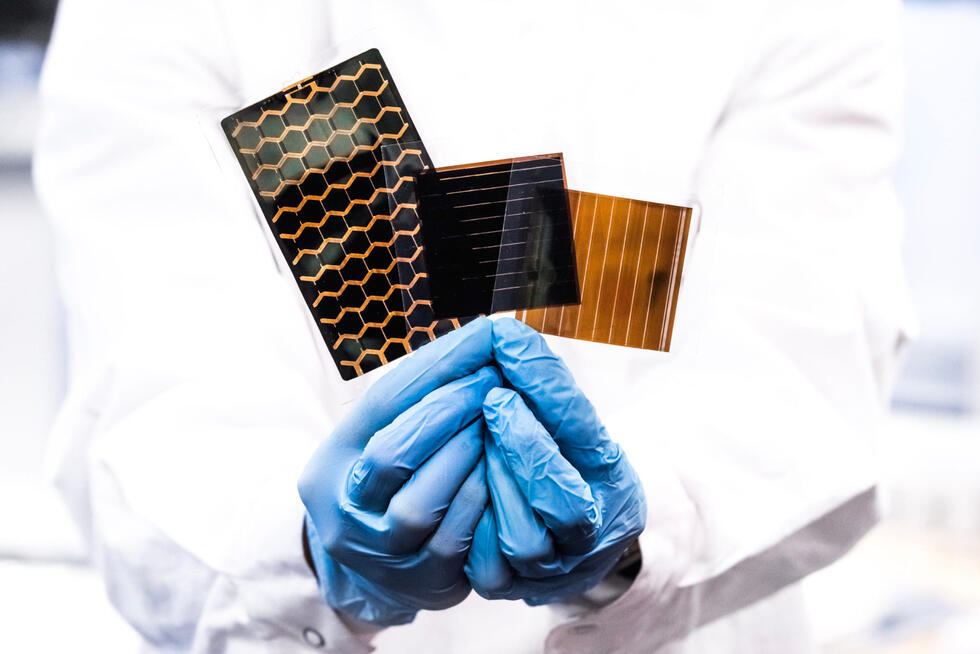

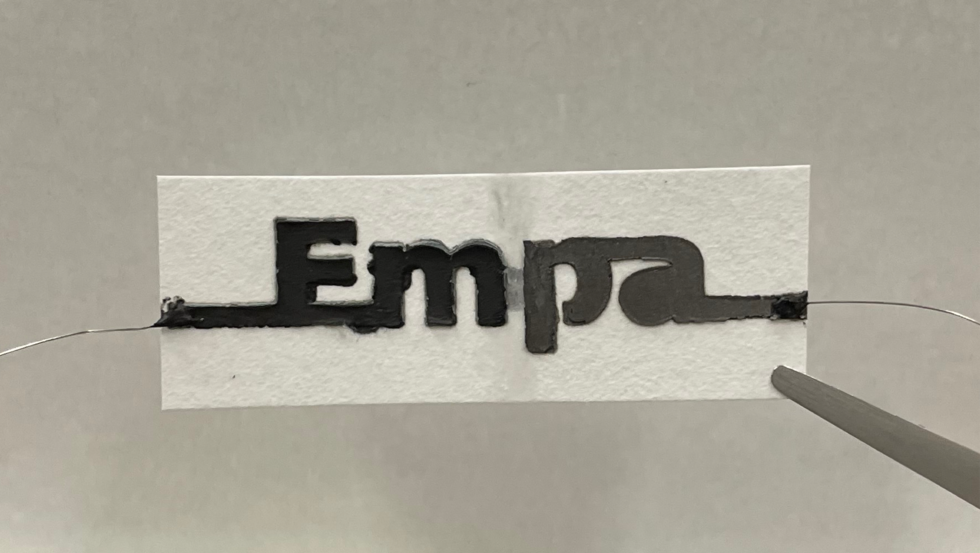

Researchers make non-recyclable plastic recyclable

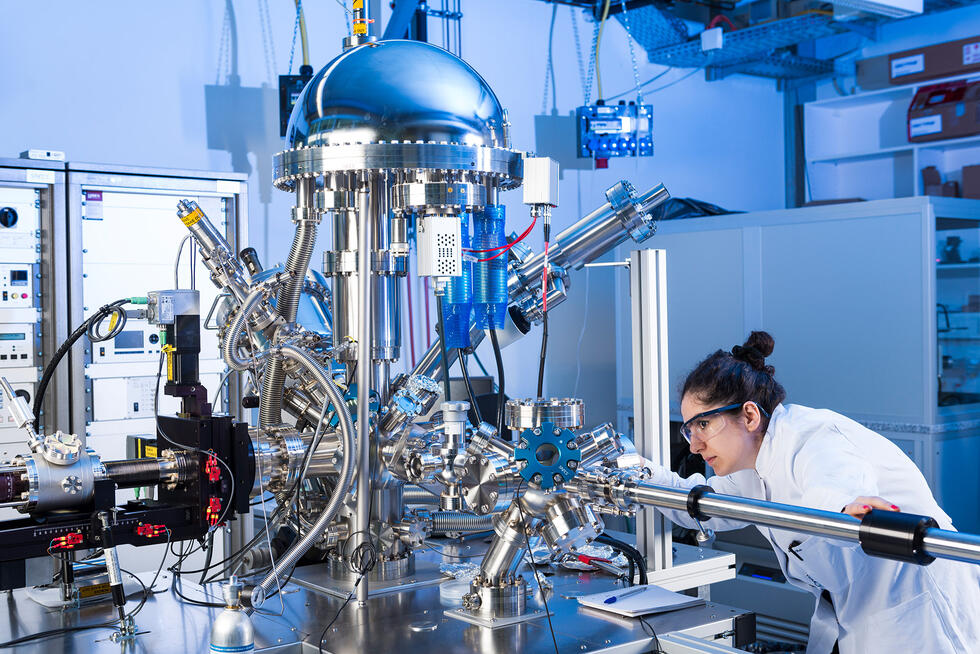

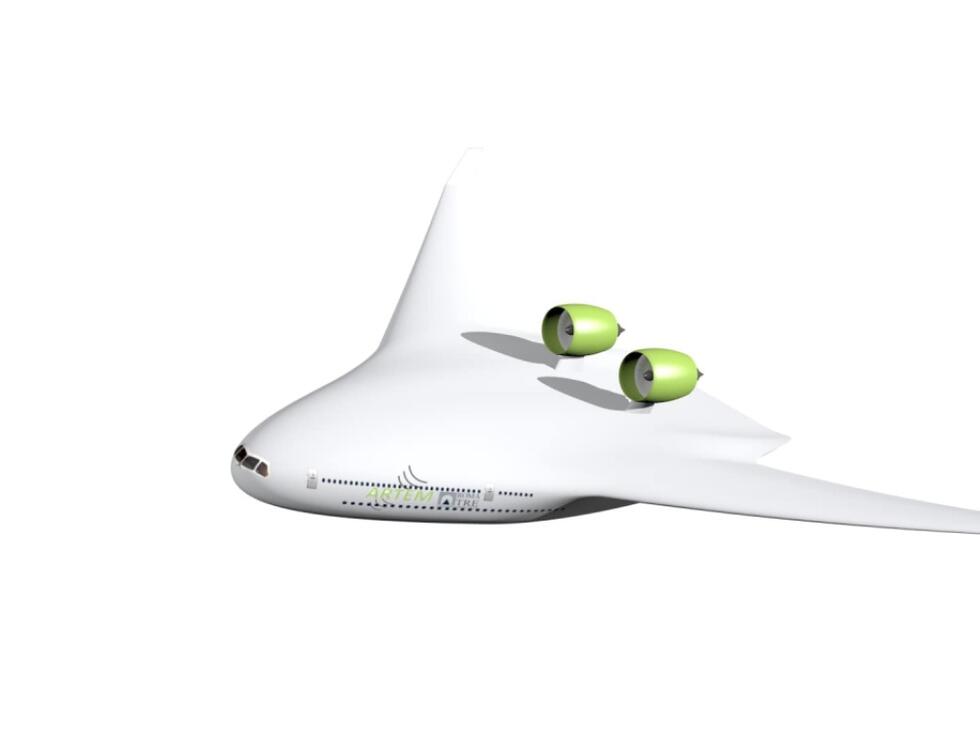

Swiss researchers have developed a new type of recyclable plastic that could be used in aircraft, cars or wind turbines in the future.

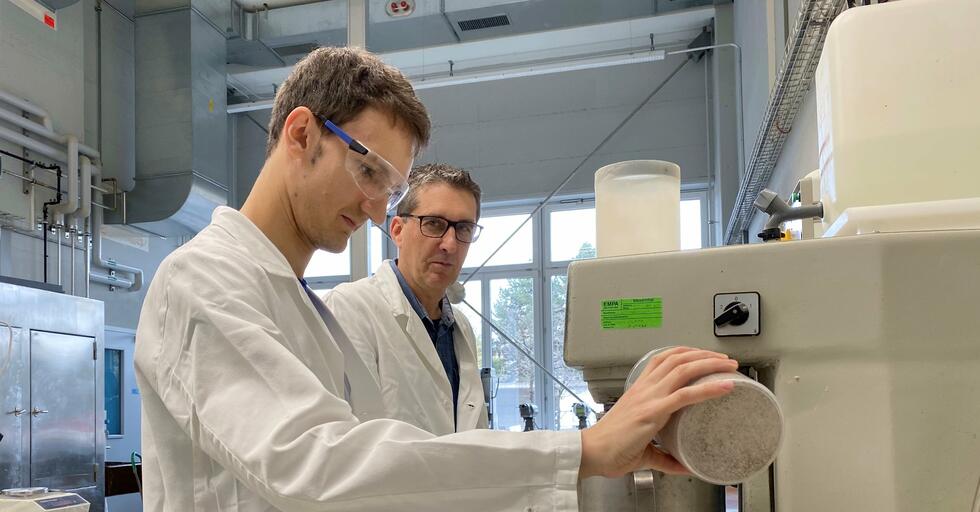

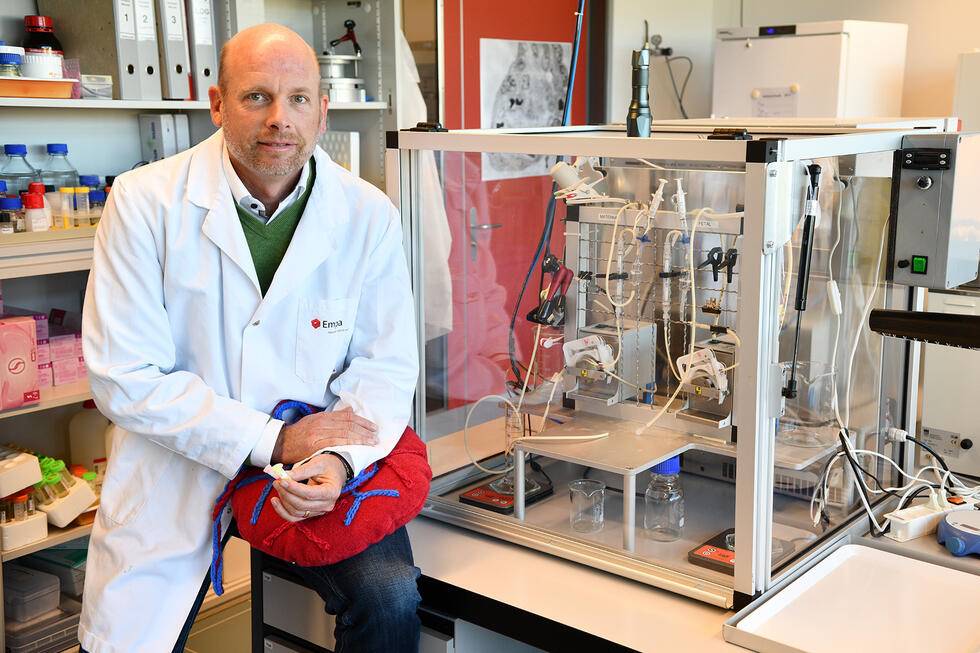

"The production of carbon fibres requires a lot of energy and releases an enormous amount of CO2," explained research group leader Sabyasachi Gaan in a statement from the Swiss Federal Laboratories for Materials Testing and Research Empa.

"If we could recycle them, their ecological footprint would be a lot better - and the price a lot lower," Gaan added. The Empa researchers have made the traditionally non-recyclable material epoxy resin recyclable for this purpose. They recently presented the new material to experts in the Chemical Engineering Journal.

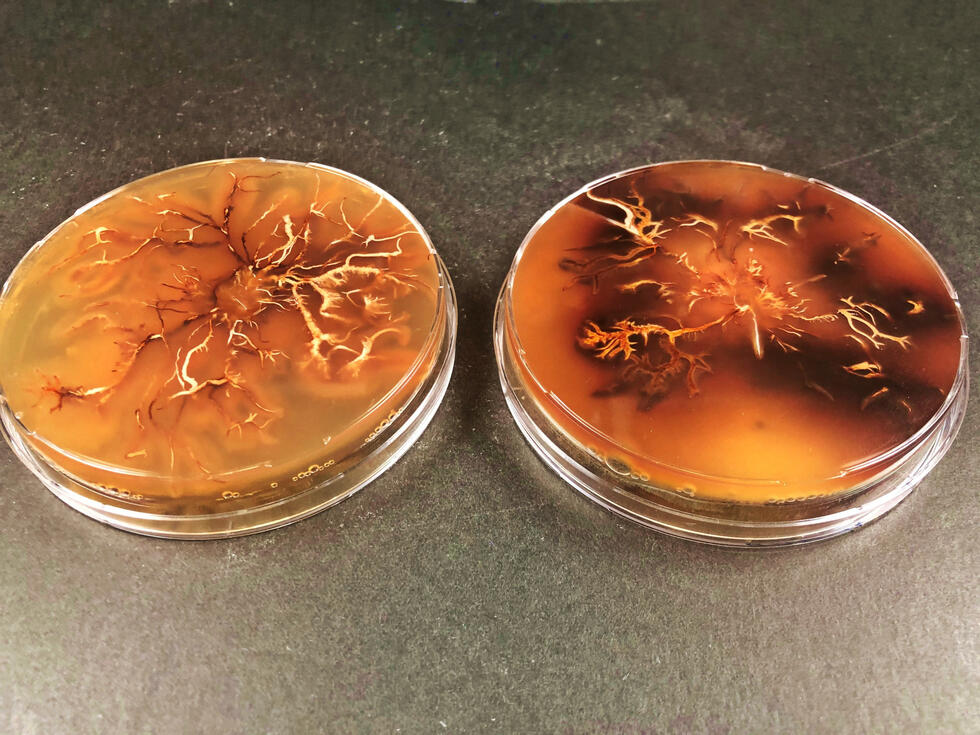

Epoxy resins belong to the so-called duromers, in which polymer chains are closely cross-linked. These cross-links prevent the plastic from melting, which is necessary for recycling. So-called thermoplastics such as PET behave differently: here the polymer chains are close together, but not cross-linked.

Resistant and flame retardant

Although this facilitates recycling, it brings other disadvantages. Because of the lack of cross-linking, their mechanical properties at elevated temperatures are generally not as advantageous as those of duromers, Empa said. According to the researchers, the new epoxy resin combines these properties: it is actually a thermoset, but can melt like a thermoplastic.

To achieve this, the scientists added a special molecule from the class of phosphonic acid esters to the epoxy resin. This molecule forms bonds with the polymer chains that can be dissolved again under certain conditions. This loosens the cross-linking of the polymer chains so that they can be melted and shaped. The result is a recyclable material that is flame retardant and mechanically resistant, according to Empa.