SHORT NEWS

Smallest stent in the world from a 4D printer

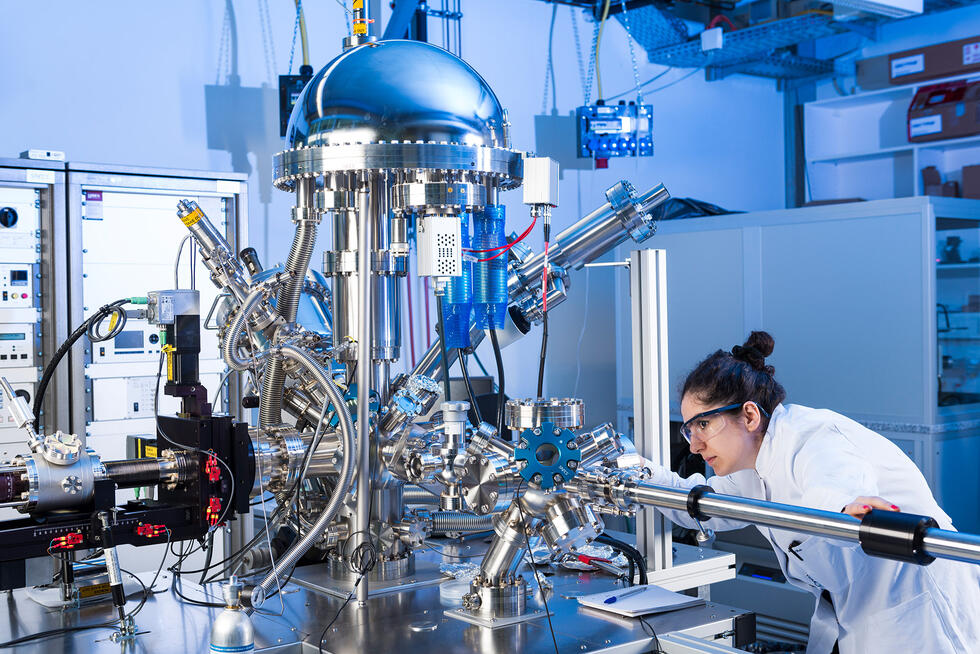

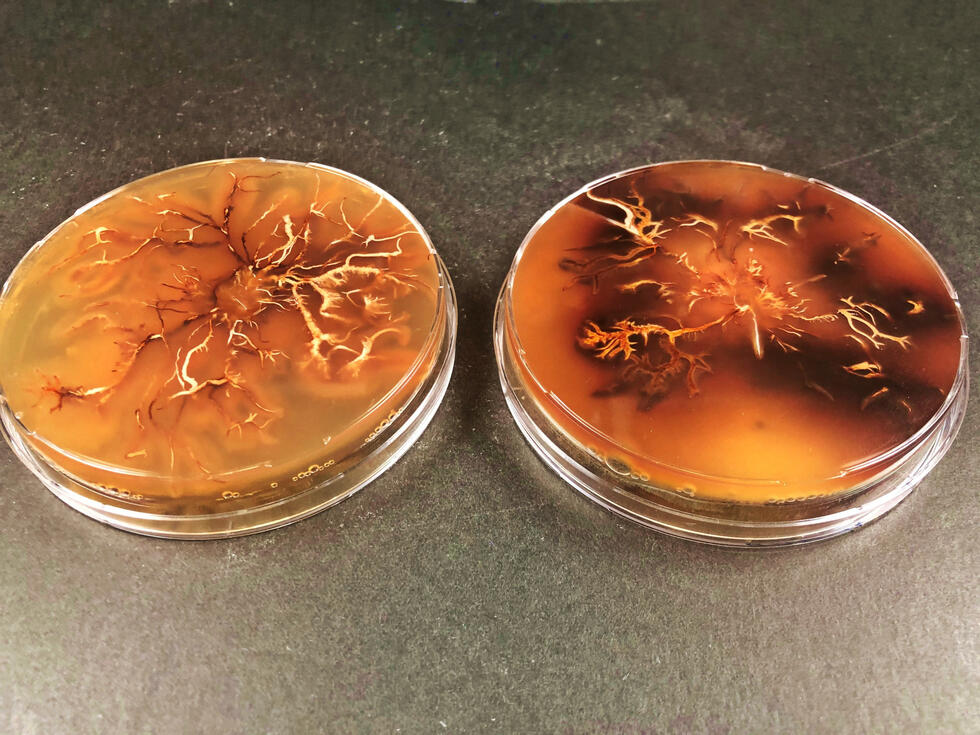

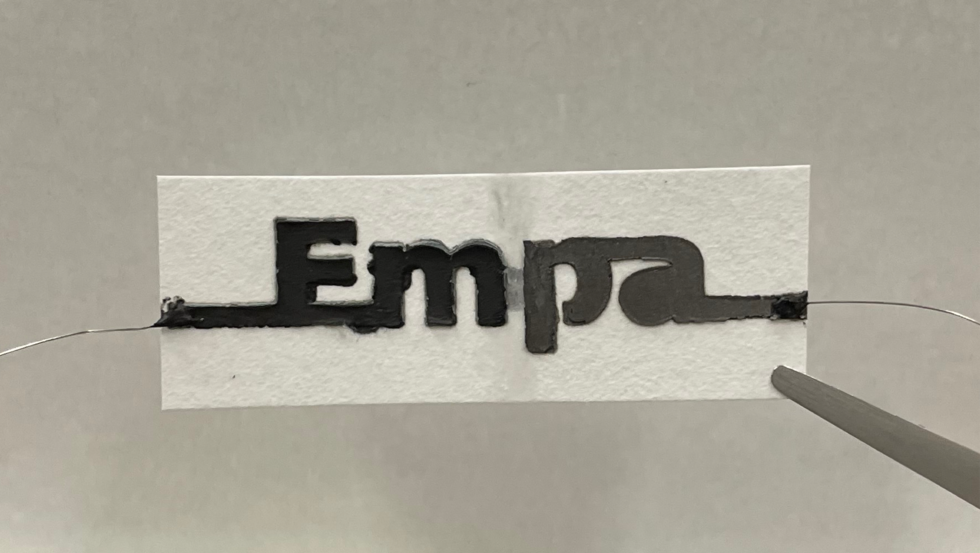

Thanks to a new process known as “indirect 4D printing”, researchers at the Swiss Federal Institute of Technology in Zurich (ETHZ) have succeeded in producing a tiny vascular prosthesis (stent). It is around 40 times smaller than was previously possible. Such mini stents could one day be used in fetuses.

Although vascular implants for narrowed coronary vessels already exist, they would have to be much smaller for the urinary tract of fetuses. However, so far it has not been possible to produce such tiny stents.

A method developed by ETH researchers to produce deformable microstructures now offers a solution. This enables the production of stents with detailed structures that are 40 times smaller than those previously produced.

After further improvements and extensive safety tests, such a mini stent could be used, for example, in the case of urinary tract constrictions in fetuses. These occur in about one in 1000 children and can lead to a potentially fatal urinary blockage.

To prevent this, pediatric surgeons have to cut out the constriction and rejoin the open ends. It would be far less invasive to use a stent to expand the constriction in the fetus while still in the womb.

Indirect 3D and 4D printing

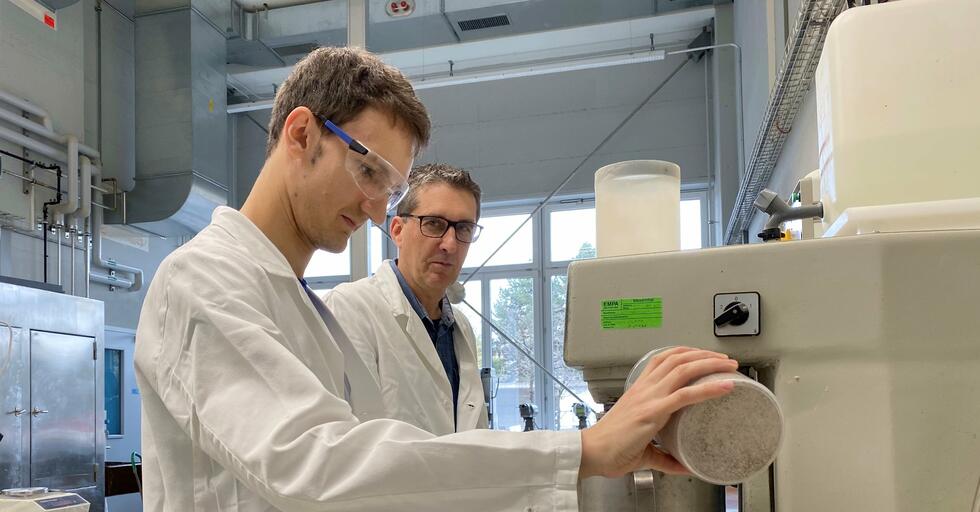

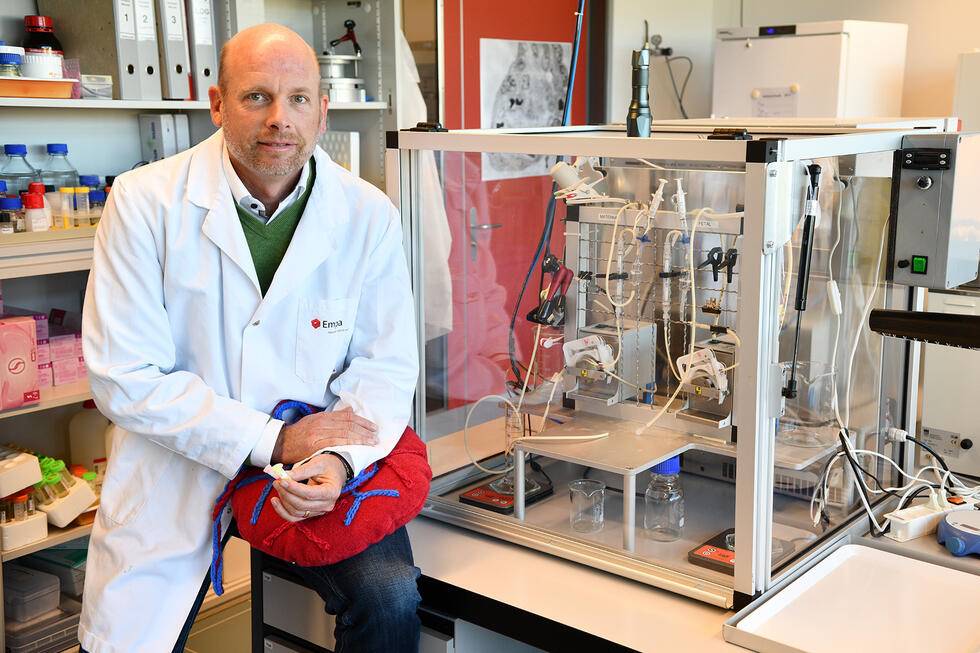

With this in mind, pediatric surgeon Gaston De Bernardis of the Aarau Cantonal Hospital turned to researchers led by Bradley Nelson from the ETH Zurich. They developed a new process called “indirect 4D printing” in order to produce detailed microstructures less than 100 micrometers in diameter.

They created a stent with a diameter of just 50 micrometers and a length of half a millimeter. They recently presented the method in the “Advanced Materials Technologies” journal.

In indirect 4D printing, the researchers first produce a 3D negative by using a laser to burn the structure into a film which is dissolvable using a solvent. They then fill this mold with what is known as a shape-memory polymer and use UV light to cure it. They release the completed three-dimensional structure from the mold by dissolving the mold in a solvent bath.

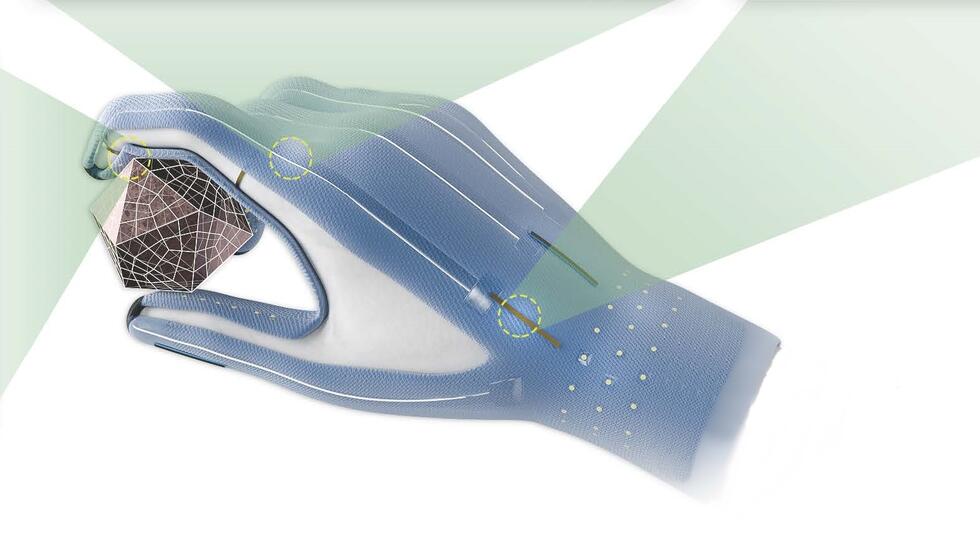

The fourth dimension results from the “shape memory” of the polymer. This allows the stent to be compressed in order to be pushed through the urinary tract into the constriction, but then it returns to its original shape. As Gaston De Bernardis explained in the press release, this opens up the constricted urinary tract.

The road to clinical application is still a long one. Nevertheless, the study’s lead author Carmela De Marco from the ETH Zurich is confident: “We are convinced that our results point the way to the development of new surgical tools for minimally invasive operations.”