SHORT NEWS

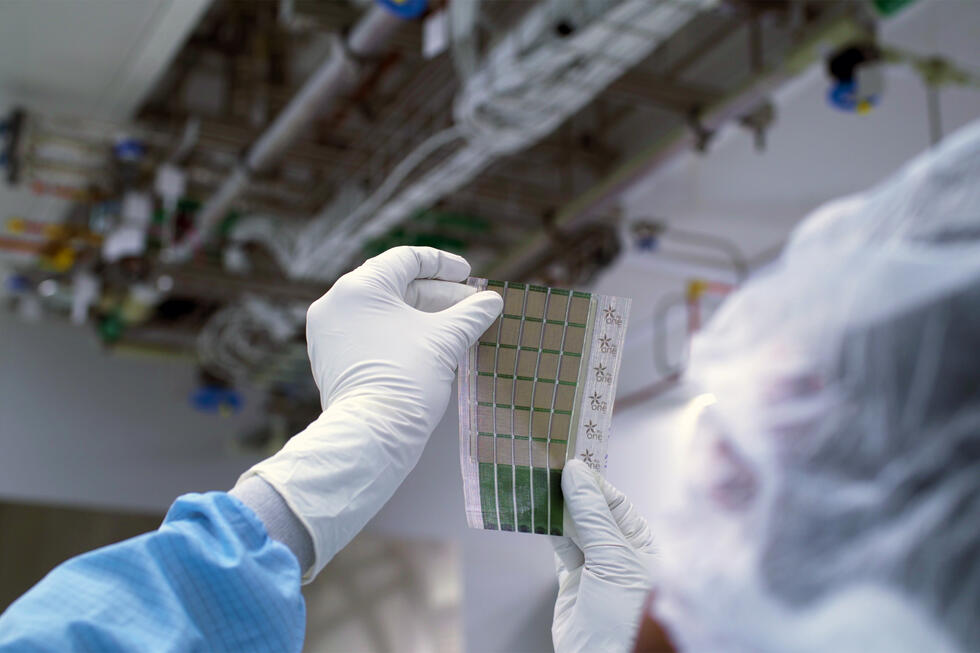

Sensors and switches made of wood

Sustainable electronic elements can be made from wood. This is helped by a novel process that uses a laser to engrave electrically conductive tracks into veneers.

Year after year, huge amounts of non-biodegradable electronic waste accumulate. Producing these instead, at least in part, from a natural raw material such as wood is not so easy: for one thing, wood is not conductive by nature, and for another, it has an uneven structure, which makes large-scale production difficult.

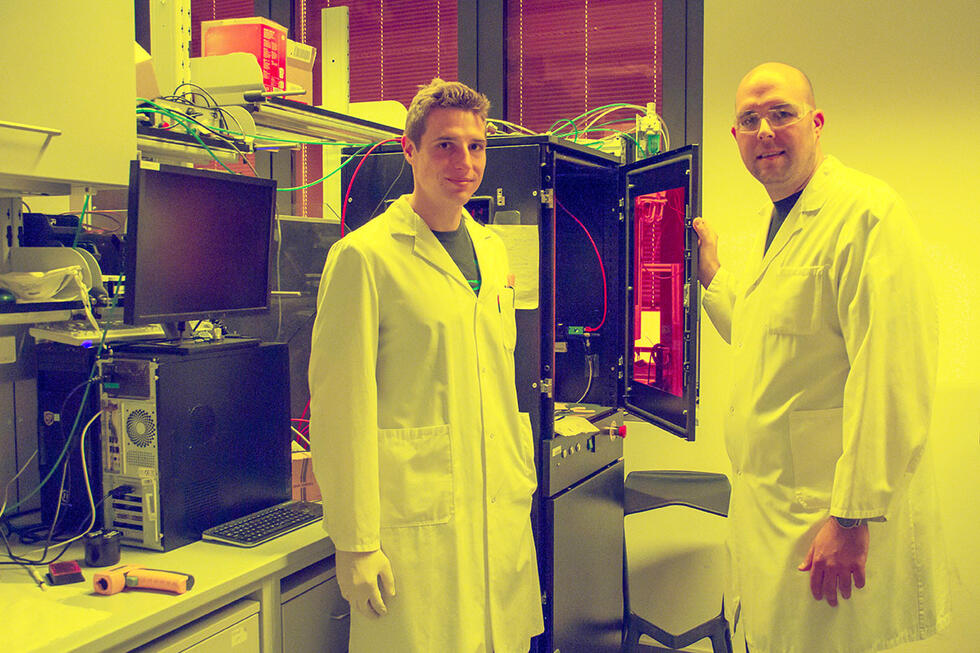

A research team from ETH Zurich and Empa has now developed a method to make the surface of the wood electrically conductive in a simple way by graphitisation, and thus to produce wood touch panels and sensors, for example. The trick: pre-treatment of the wood with an iron-containing ink.

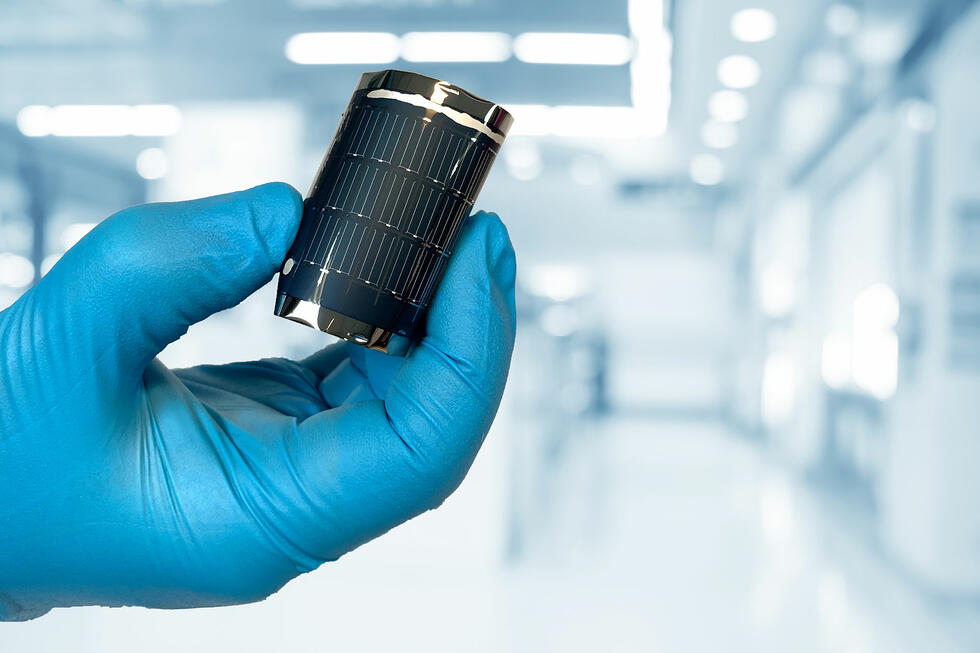

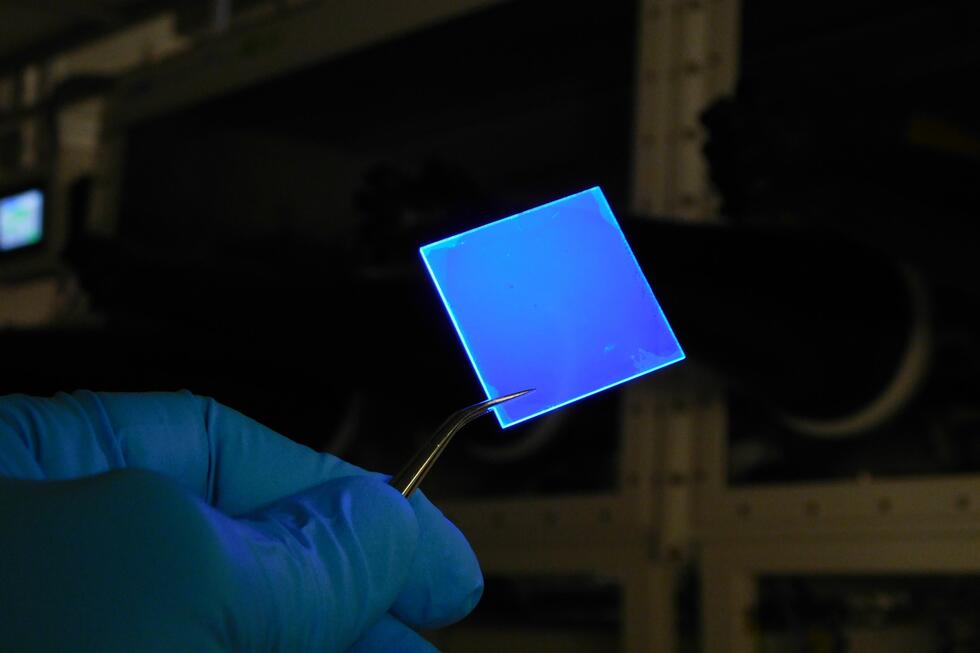

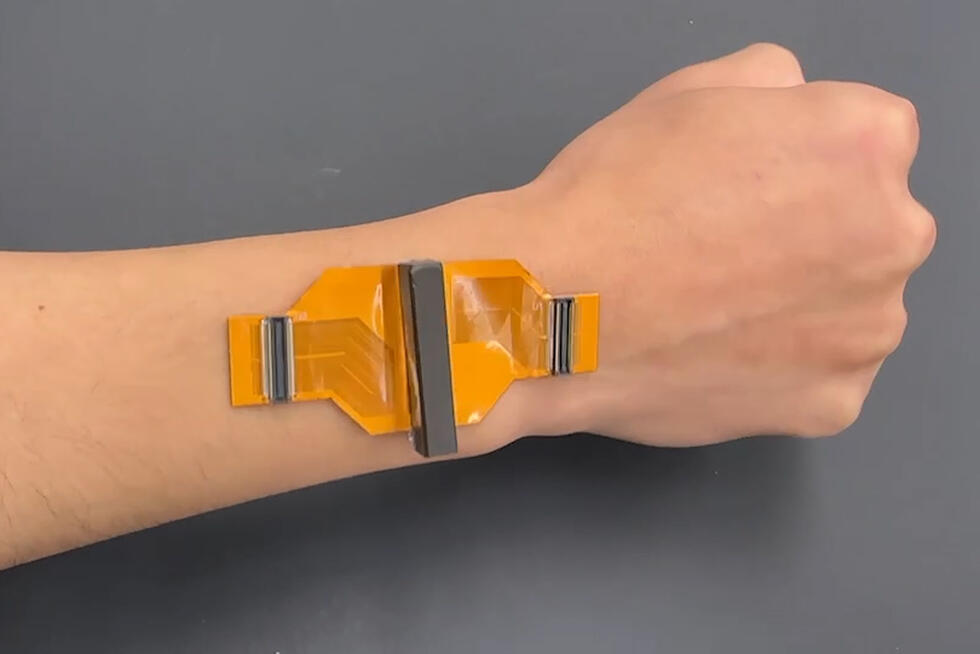

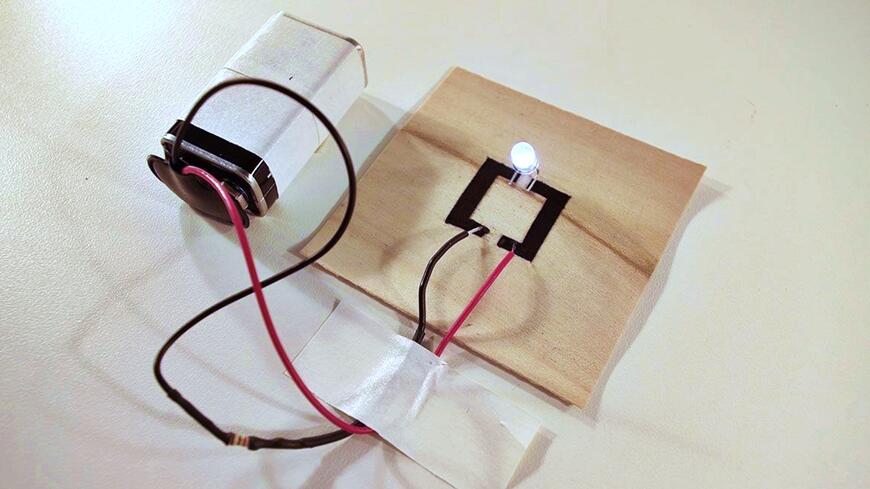

Bendable sensors and light elements

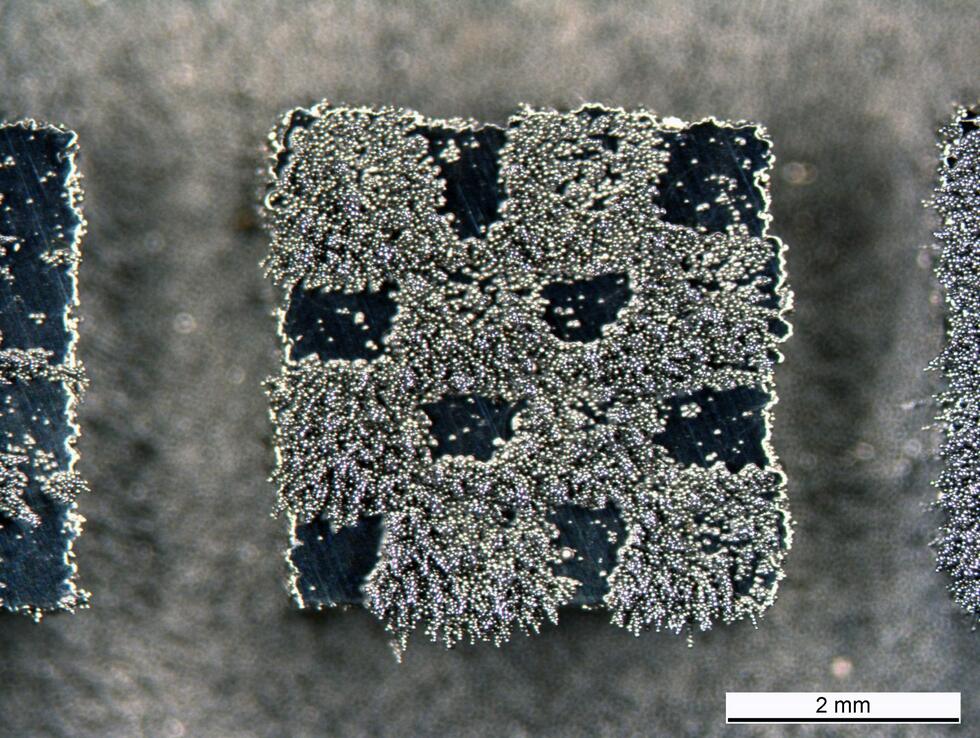

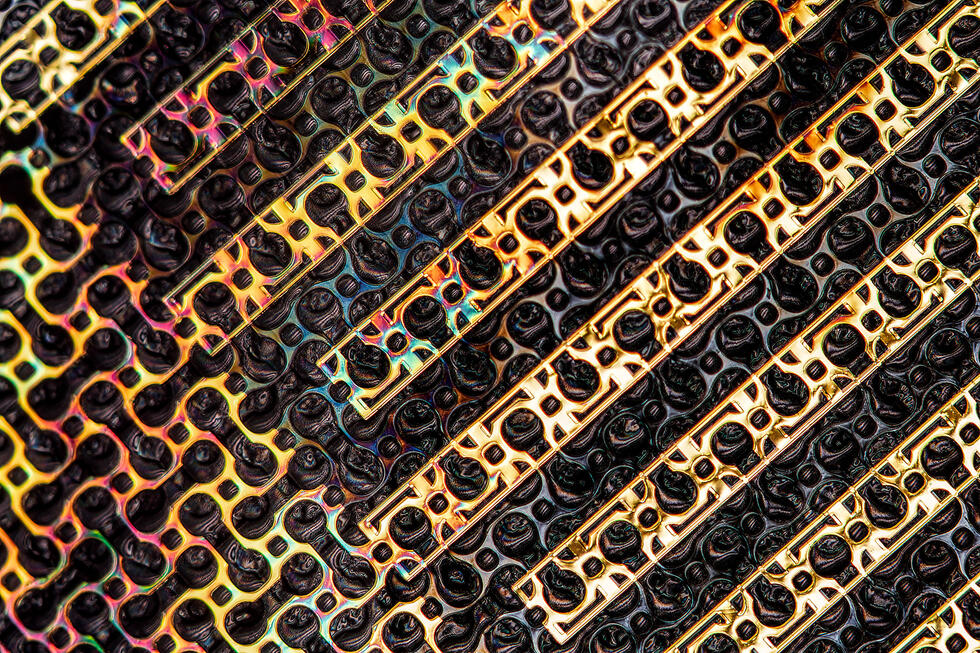

The new method is based on an already known procedure, the so-called laser-induced graphitisation, to create conductive tracks on wood: For this purpose, a laser engraves fine lines into thin wooden plates - in the process, the energy of the laser beam heats the wood in such a way that the carbon contained in it transforms into conductive graphite. However, the conductor paths created in this way are irregularly wide and deep, and there is also a risk of fire due to overheating. Multiple post-processing with the laser is also often necessary.

The researchers therefore used iron ink as a catalyst - this enables a gentler process and leads to a significantly more homogeneous surface. They brushed the ink in a thin layer onto various wood veneers and then treated them with the laser.

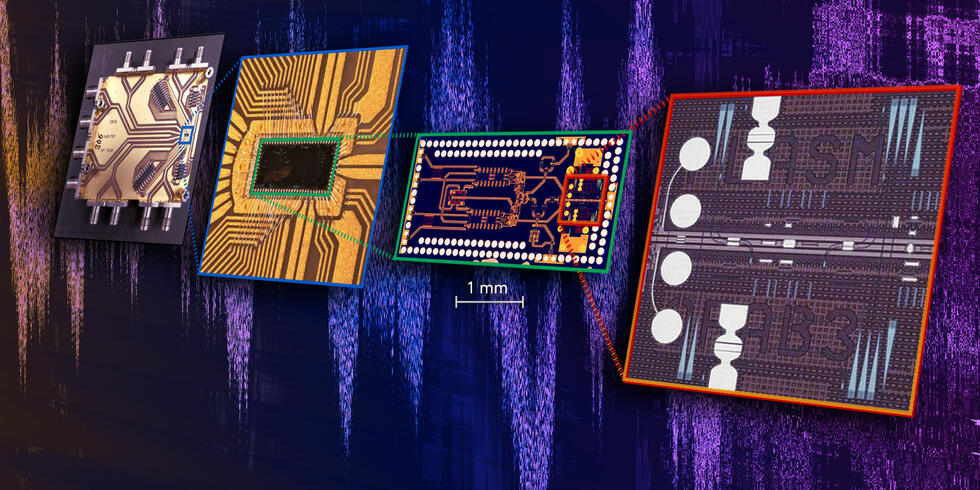

As a practical test, the team used this method to produce trial electronic elements from spruce, cherry and beech veneers less than half a millimetre thick. These could be used, for example, as bendable strain sensors that could monitor load-bearing components in the construction industry. Or as lighting elements for the backlighting of displays, advertisements or control panels.