Revolution in the berry patch

Some 30 years ago, a Canadian researcher discovered an environmentally friendly way to deploy bees in the fight against grey mold. This approach, which holds a lot of promise for European fruit growers, is currently being tested on Swiss berry patches.

Business is buzzing on the Räss Wild Berry Farm in Benken, near Zurich: Six years ago, when the brothers Simon and Christoph Räss took over the farm from their parents, they decided to literally start from the ground up and, rather than growing potatoes like their parents did, to start planting all kinds of berries – strawberries, blackberries, currants, and even some more exotic varieties, like Japanese goji berries and aronia, which originated in North America. And they decided to grow them organically, without using any artificial fertilizers or pesticides: “We put everything we had into berries”, admits Simon. “It was a vastly underserved market, because at the time, virtually nobody was growing organic berries in Switzerland.” And as it seems, their venture paid off: For about three years after the relaunch, the Räss Wild Berry Farm had to live off its financial reserves, but since 2019, the farm is back in the black and doing well: “Not wanting to brag, but we are dominating the Swiss market for organic berries.”

One hundred workers and 50 bumblebee hives

The Räss brothers, assisted by Christoph’s girlfriend Michelle Schuhmann, have planted their organic berries on almost 75 acres (30 hectares); half of which is used to grow currants and aronia for the food industry, primarily to make juice and dried berries (which, for example, are frequently added to muesli): “Growing and harvesting these berries is mechanized”, Simon Räss admits. But the remaining 15 hectares are dedicated to growing organic berries for fresh consumption, mainly for the local markets: “Most of our berries are eaten in Zurich and Winterthur.” They are either sold in the Räss farm store, at the nearby farmers’ market in Ossingen, or in supermarkets. These berries require “work-intensive manual labor”, Simon explains: During the growing season, which starts when strawberries blossom in April and lasts until November, when raspberries are ripe, some 100 farmhands work on the Räss farm. And at any given time, there are also 50 active bumblebee hives, which not only pollinate the berries, but also play a crucial role in plant protection.

Grey mold causes substantial losses in our strawberry crop, especially later in the season – in extreme cases, half of our harvest can be affected

Organic farming is not only more labor-intensive than conventional farming, it also comes with significant crop losses, mainly caused by Botrytis cinerea, which is commonly known as grey mold, and is a bane of every farmer: “Grey mold causes substantial losses in our strawberry crop, especially later in the season – in extreme cases, half of our harvest can be affected,” Simon explains. But unlike conventional growers, organic farmers don’t have many options to combat this plant fungus.

Switzerland as a gateway to the European market

But then, some eighteen months ago, Simon’s father Hans found an article in a trade journal about the Canadian company Bee Vectoring Technology, which specializes in using bumblebees to combat Botrytis in an environmentally sustainable way. Simon Räss was immediately intrigued: “We use bumblebees anyhow, since they pollinate our early strawberry crop.” Unlike honeybees, which need much warmer weather and therefore only appear later in the season, bumblebees start flying at temperatures just a few degrees above freezing. And when Simon approached the Canadian company, Bee Vectoring Technologies responded immediately: “We had already decided that Switzerland should be our gateway into the European market”, explains Ashish Malik, the CEO of the company. “Regulations are much easier in Switzerland than in the EU, but otherwise it is very comparable.”

Sac fungi versus grey mold

The story how bumblebees became useful crop protectors began ten years ago in Mississauga, a suburb of Toronto (Canada), when John Sutton, a quirky professor emeritus in biology, and two of his colleagues from the University of Guelph (Ontario) paid a visit to Michael Collinson: “At that time, I was running an office furniture factory, and one day, these three characters knocked on my door and asked me if I could help them with some plastic work,” Collinson told me when I first visited him four years ago. At first, he was quite flummoxed when the three scientists started talking about the gray mold Botrytis cinerea, and about a particular sac fungus called Clonostachys rosea, which does not even have an everyday name, although it is fairly common, mainly in soil.

Every strawberry, every almond, every raspberry was once a flower, which had to be visited at least once by a bee or a bumblebee – no fruit without pollination

As Sutton serendipitously discovered in the 1970s, C. rosea has a very useful characteristic: The filaments that this fungus inserts into the plant tissue prevent other – far more harmful – fungi, like the grey mold, from taking hold. But it took until the early 90s for Sutton to come up with the idea to use bees as carriers (what biologists call a “vector”) for this useful fungus. “We found that Clonostachys is most effective when it enters the plant directly through the flower”, Sutton explained to me. “And every strawberry, every almond, every raspberry was once a flower, which had to be visited at least once by a bee or a bumblebee – no fruit without pollination.” From there, the idea of using bees as carriers for “Bee Vectoring” started to take shape.

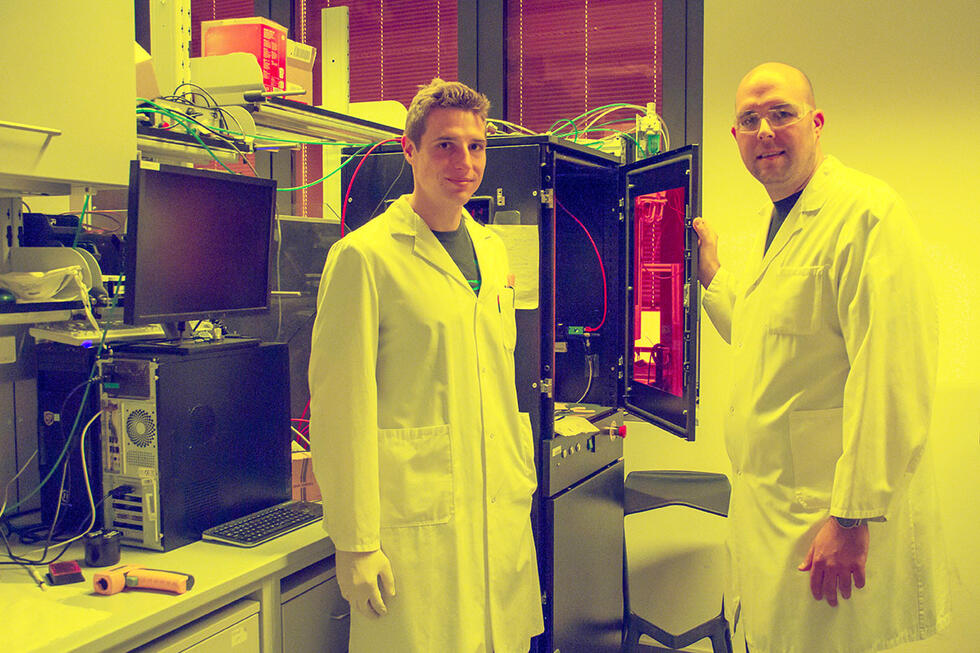

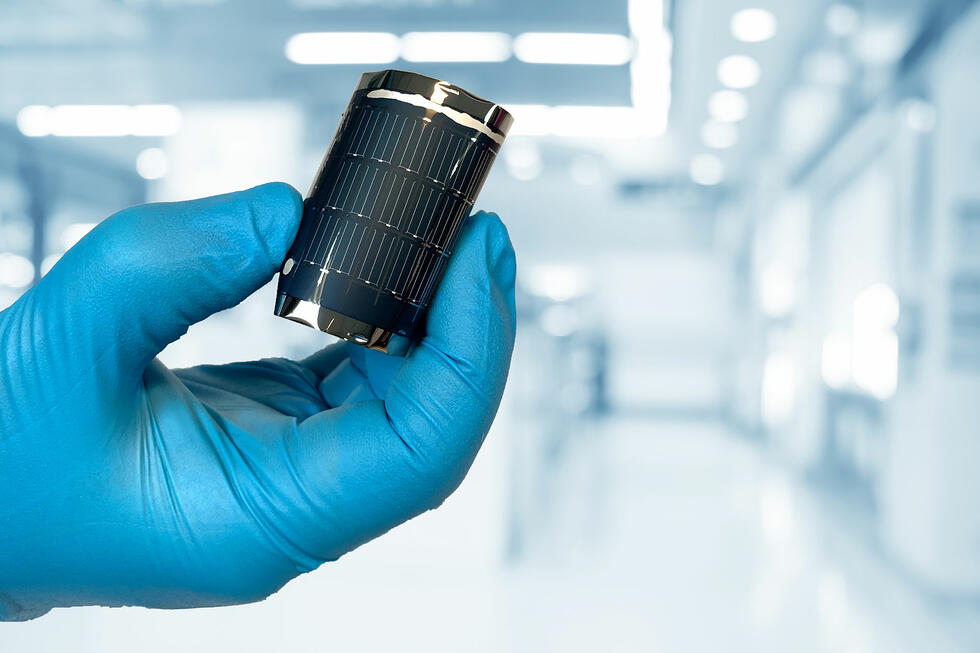

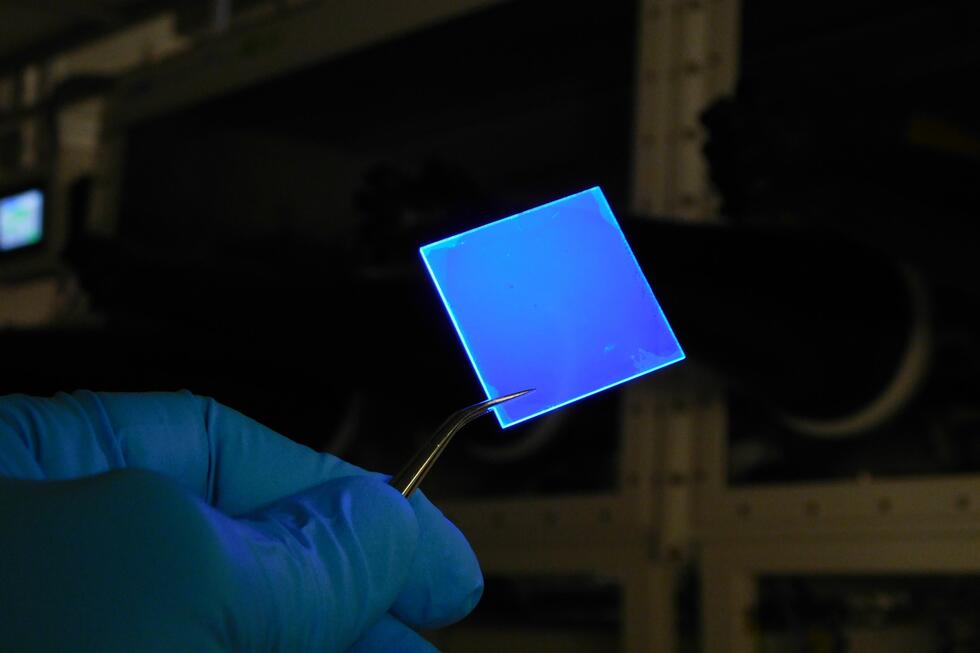

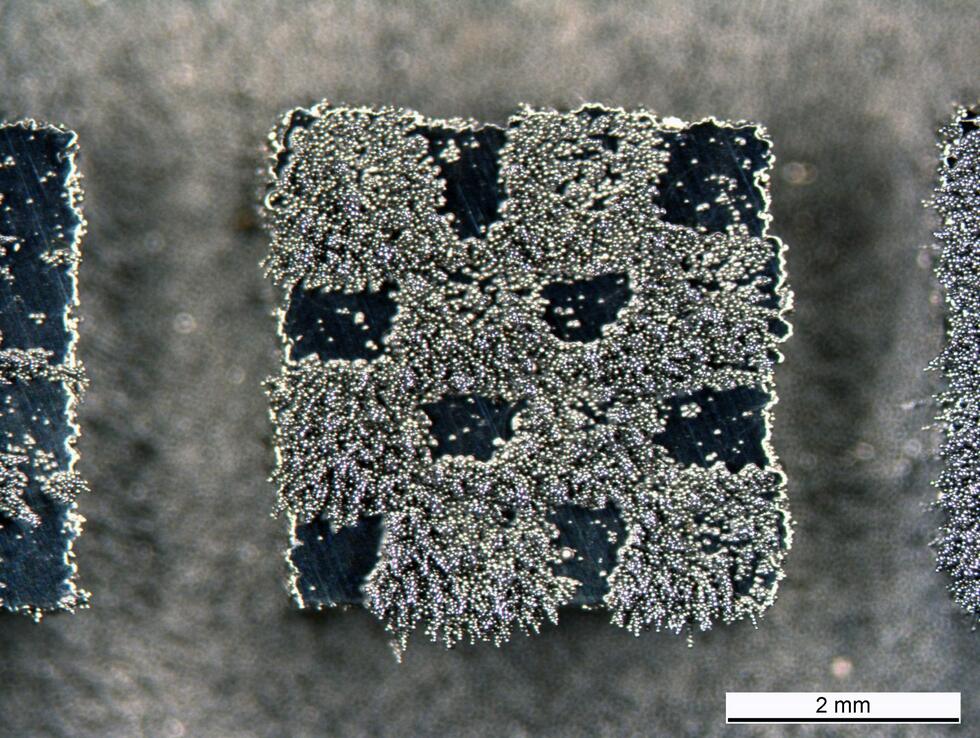

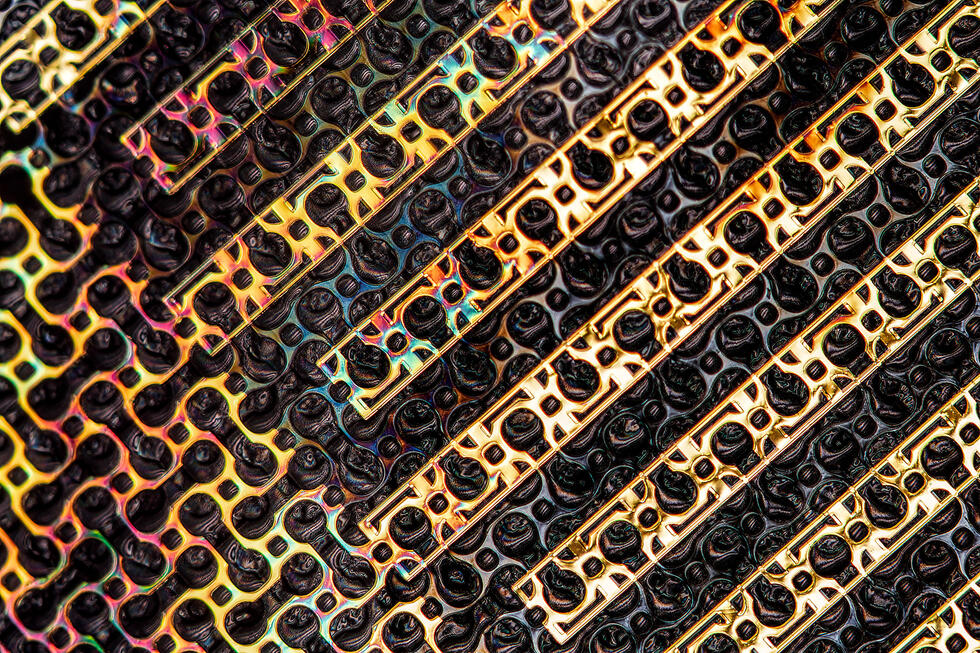

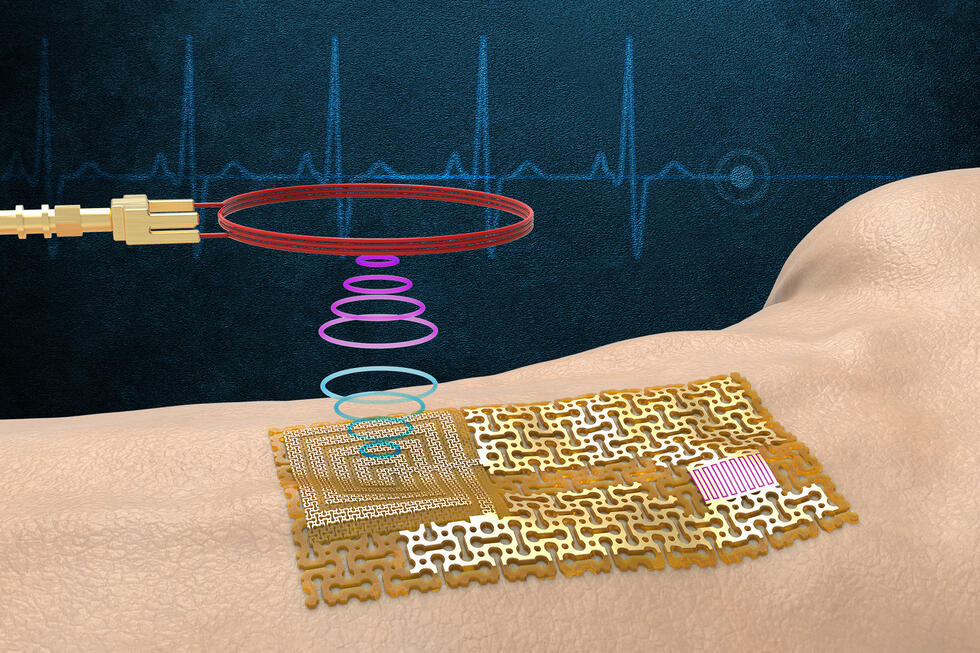

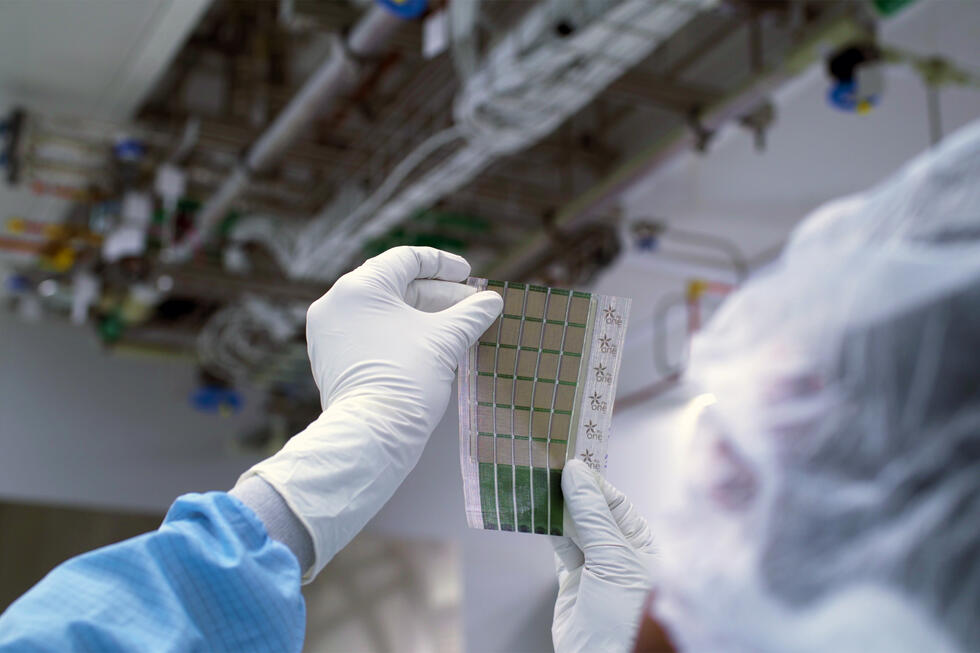

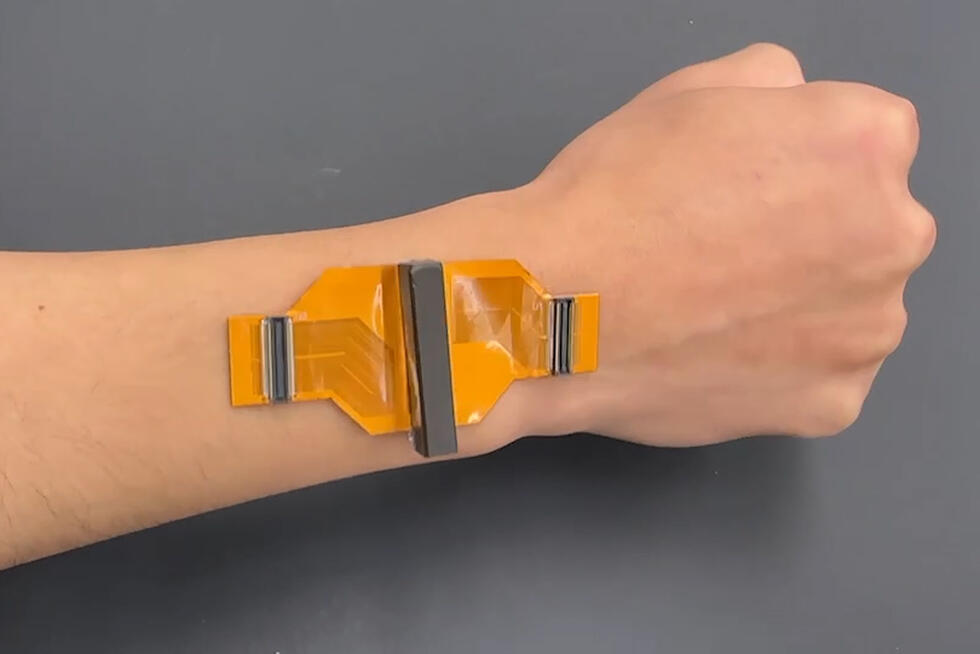

Working with his colleagues Todd Mason and Peter Kevan at Guelph, Sutton developed a method to produce a powderized form of Clonostachys rosea, which pollinators can carry from their hives to the plants: They cultivated the fungus in dark climate chambers, growing it on a substrate of barley before drying the spores and mixing them with fructose and several other ingredients and a patented carrier material which they named “Vectorite”. The researchers determined that bumblebees would be the perfect delivery system: They are far less aggressive that honeybees, live in smaller hives (comprising only a few hundred individuals), and do not need a great deal of special care, unlike honeybees. Finding a supply of bumblebees was also easy: Companies like Koppert in the Netherlands already specialize in shipping bumblebee hives in easy-to-use cardboard boxes to customers all over Europe and the United States. And loading the Clonostachys powder – sold commercially as CR-7 – on bumblebees is made particularly easy by their behavior: All it needs is a plastic tray that is strategically placed at the hive entrance and that forces the worker bees to crawl over the powder when they fly out.

But while this system works easily in theory, there were still some practical challenges: “You can’t just use any kind of tray”, explains Sutton. “We experimented with several designs and materials, including wood.” But nothing seemed to work well – until someone suggested that the scientists reach out to Michael Collinson. He was flattered, but after all “plastics are my expertise” – as are numbers, which he quickly calculated in his head: It takes 15 bumblebee hives to pollinate one hectare of strawberries; each hive will go through seven of these trays during the three weeks when strawberries are in bloom, and there are 24,000 hectares of strawberry fields in the USA alone. “A nice little business,” he thought to himself. A few months later, he sold his shares in the furniture factory and – together with Sutton, Mason, and Kevan – launched the company Bee Vectoring Technologies.

Money from the stock exchange, know-how from the competition

Initially, the company consisted of not much more than a business idea, a few patents (among others on Vectorite, but also on a proprietary method of growing the specific strain of Clonostachys fungus commercially), and some seed money, which Collinson contributed. But it takes more than ideas in this business – especially in the multi-billion plant protection sector. In principle, CR7 a natural, biological substance and as such comparable to natural food supplements, which are far less regulated than pharmaceuticals and do not need to undergo expensive clinical studies. But CR7 still needed approval from the US Food and Drug Administration (FDA), and this came with an 800,000 dollar price tag.

To procure the money they needed, the four founders looked to the capital markets: BVT was incorporated as a capital pool company – a special Canadian corporate structure created specifically for startup companies with high risk and minimal assets – and in May 2021, they took Bee Vectoring public on the Toronto Stock Exchange; since October 2015, the company has also been listed on the Frankfurt Stock Exchange. And for the necessary know-how to manage such a company, they hired Ashish Malik, who came from Bayer CropScience and took over the helm from Michael Collinson in August 2016.

Bees as a billion-dollar business

Malik has an intimate understanding of the agribusiness. And he knew: The big bucks are not made with bumblebees, but with honeybees. In California alone, farmers deploy more than one million beehives as pollinators every year. Over 1600 beekeepers offer such pollination services, each renting out hundreds of beehives to growers of almonds, strawberries, tomatoes, citrus, and whatever else might currently be growing on Californian fields. It’s a billion-dollar business. And that does not even take into account the 2000 dollars per hectare that the average US fruit farmer spends on pesticides each year.

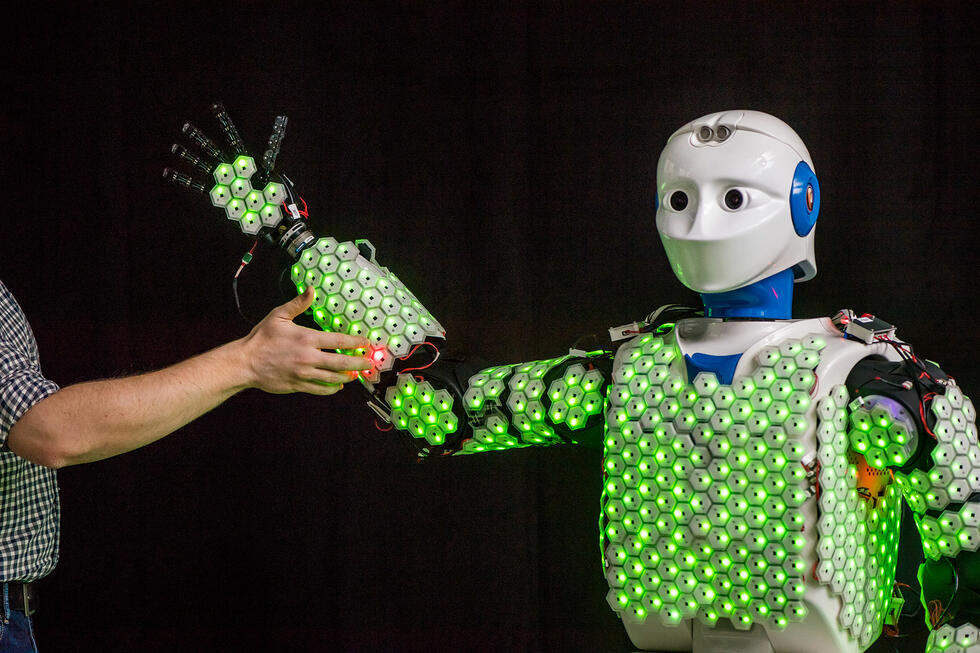

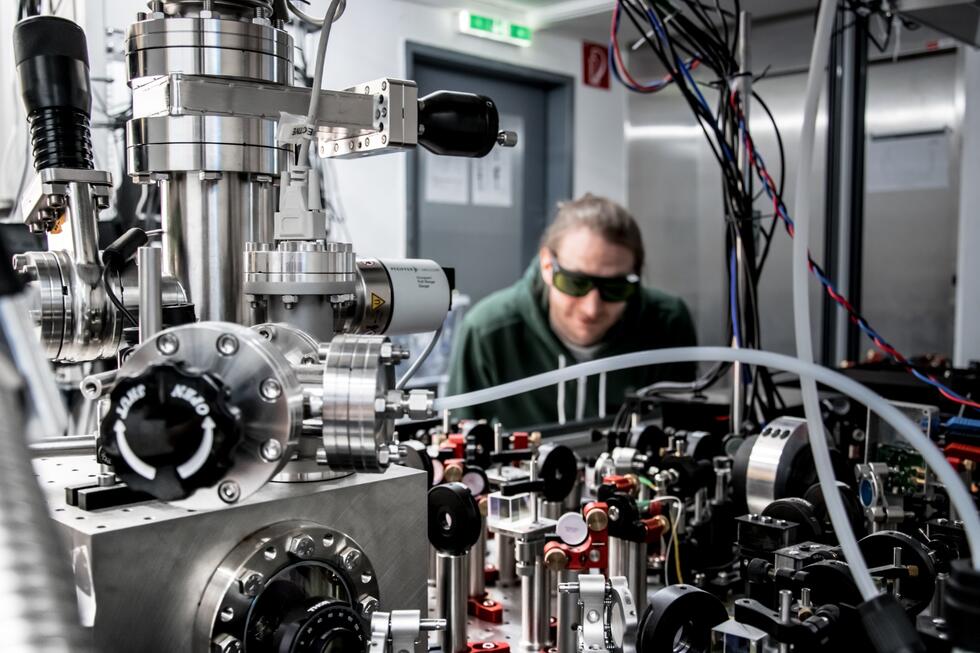

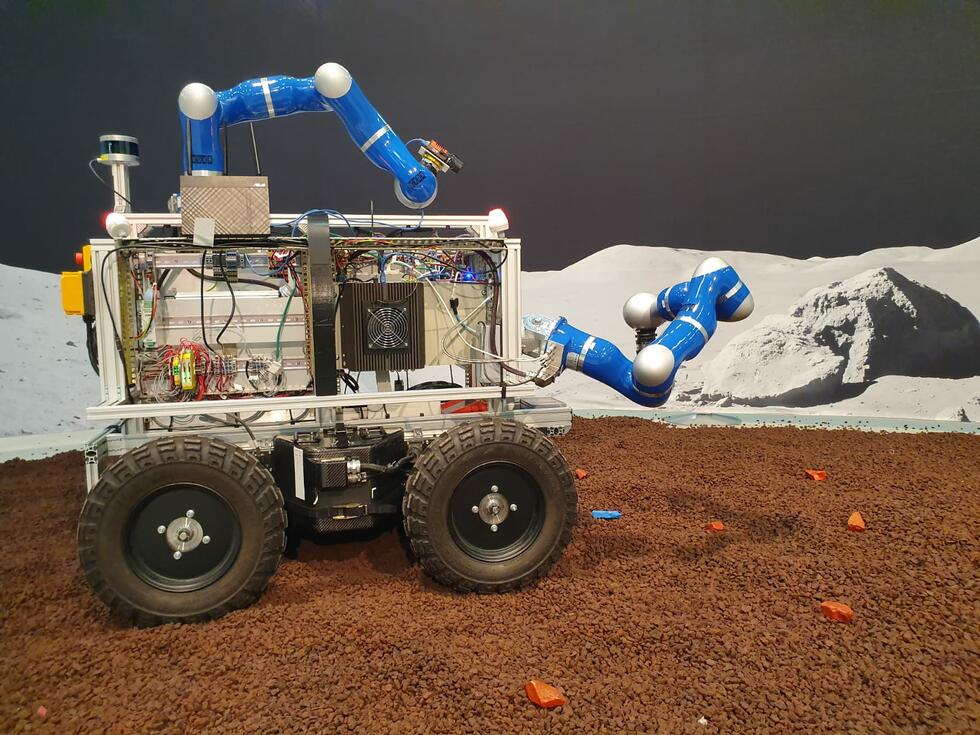

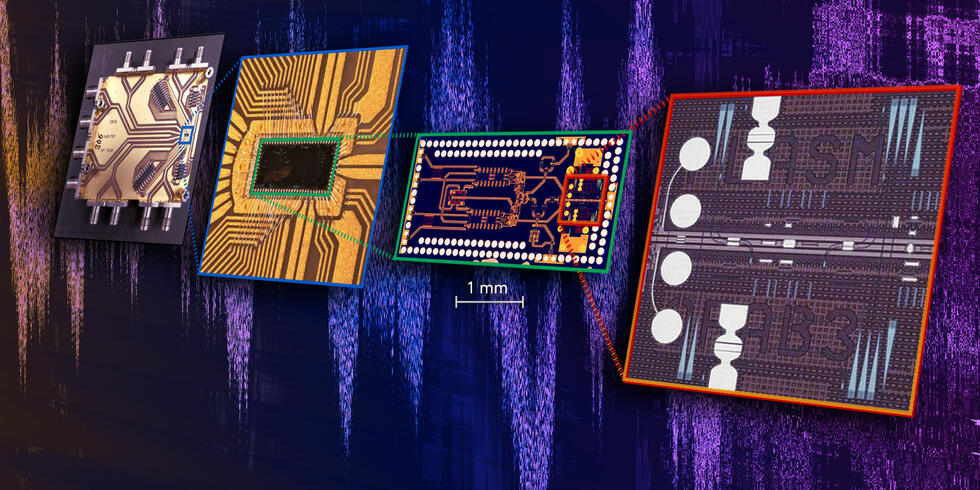

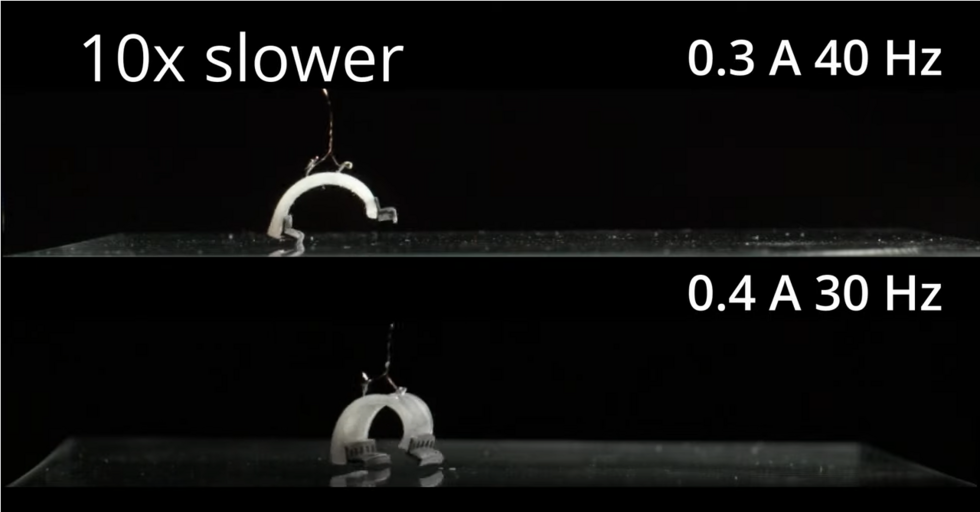

While each individual bumblebee hive generates around 150 dollars in revenue, honeybees can bring in more than twice the amount per hive and job. But vectoring with honeybees is not as easy as using bumblebees: Their hive population is about one hundred times larger than that of bumblebees, and they won’t simply crawl over the Vectorite powder when exiting their bee boxes. To use honeybees, BVT had to develop and patent special computerized dispensing systems, which can simply be mounted “in less than half a minute using a few wood screws” – as Malik assures – above the entrance of the bee boxes.

But not only the technology, also the business model is more complex with honeybees: The actual customers who pay for the bee vectoring service are the growers, but the beekeepers, on whose boxes the Vectorite dispensers will eventually be mounted, also have to come on board. The dispensers, in turn, are owned and serviced by Bee Vectoring technicians. Which sounds like a lot of work and effort for Bee Vectoring Technologies, but according to Malik, it is quite manageable: Three employees are all it takes to take care of BVT’s current 30 customers in the US – some of them large farming enterprises on the west coast, and also some blueberry growers in Michigan. And they have sufficient capacities, even if the number of customers would double.

Looking for new applications

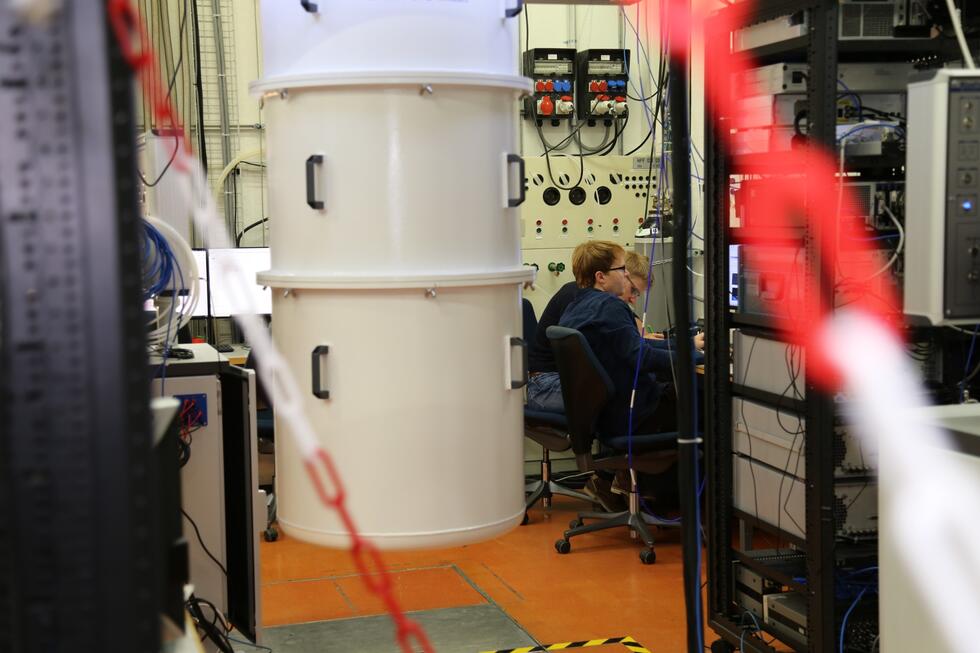

Bee Vectoring intends to grow not only in the USA, but mainly also in Europe. And Switzerland is their first step into this market: Christoph Lehnen, a 30-year veteran in agrotechnology, is managing this Swiss project from his office on the AgriCo research campus in Saint-Aubin (Fribourg). Some 90 hectares of rapeseed that grow in the fields surrounding the AgriCo campus are being pollinated by honeybees, using the latest Bee Vectoring technology. The goal is to test if Clonostachys rosea can protect rapeseed not only from grey mold (Botrytis), but also from stem rot, which is caused by another type of fungus, called Slerotinia sclerotinorium, and which is a major cause for rapeseed crop loss. Lehnen hopes to eventually expand these trials to sunflowers.

Such new crop applications are critical to make Bee Vectoring a sustainable success: “We already are testing four new products,” Malik emphasizes. One of which is of special interest to beekeepers: It involves a fungus that can destroy the dreaded Varroa mite, one of the most devastating pests in honeybee hives. According to Malik, the initial feedback from beekeepers has been “quite positive”. And that’s good news for his company: The current business model generates a mere 600,000 Dollars in revenue, as Malik explains – probably not even enough to cover the expenses, even for a company that only has a dozen employees on payroll. The revenue from the Swiss trials is actually zero, since all participating farmers are supplied with BVT-CR7 for free – at least until the trials have been completed, and resulted in a regulatory approval for the product.

Initial tests showed a 46-percent increase in strawberry yield

But regulators are not even the biggest obstacle to success – farmers are: “Farmers are interesting characters”, says Collinson, and it does not sound entirely like a compliment: “Their land means everything to them.” And that makes them reluctant to experiment: Collinson still recalls how hard it was to convince even a single local strawberry grower near Toronto to try out the bumblebee method – “despite the fact that initial tests showed a 46-percent increase in strawberry yield”. Not every grower will eventually see such results, but considering that each hectare of strawberry fields generates an annual revenue of 100,000 euro, even a ten percent increase in crop yield would substantially improve the farmers’ income; an added benefit is that consumers are willing to pay substantially higher prices for organically grown berries. Given these results, one might expect to find strawberry farmers lining up for BVT products.

Simon Räss, the Swiss berry farmer, stands in the front of this line, metaphorically speaking: He is “absolutely enthusiastic” about Bee Vectoring. In his opinion, this method “meets the zeitgeist in Switzerland – something we would already have needed a long time ago.” He and his family are “totally convinced – last year’s results were to our satisfaction, the application is simple and quick, user friendly and hazard-free.” Exchanging the Vectorite trays requires minimal effort: “All I have to do is change the powder in the bumblebee box twice a week, that’s it. I don’t need a tractor, I don’t need to spray anything, and I generate virtually no CO2, because I can transport the powder on my bike. It’s all positive!”

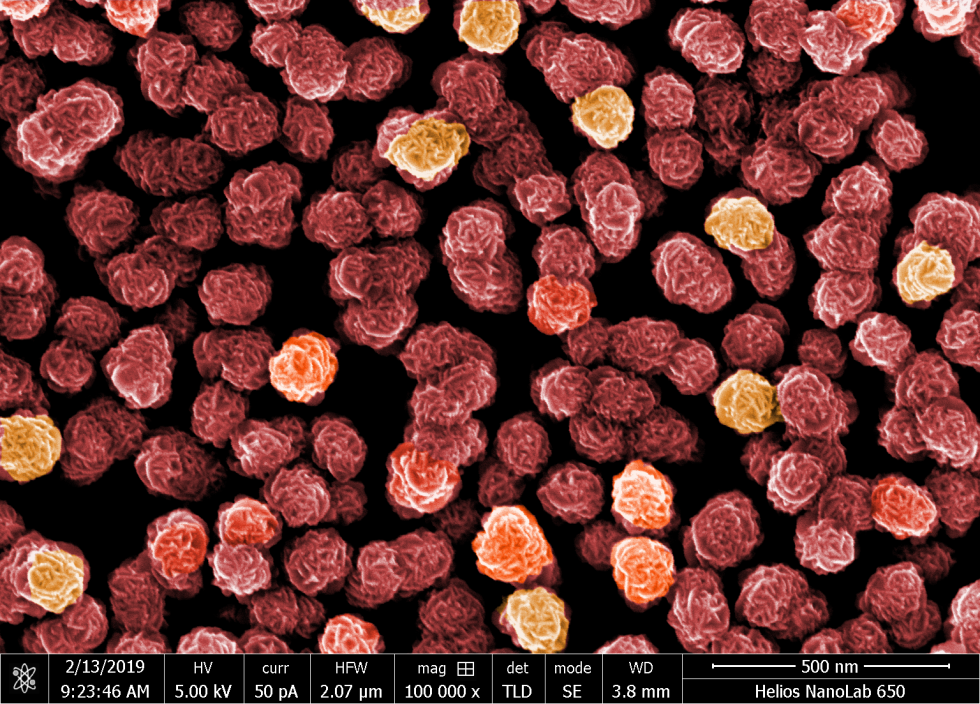

Botrytis cinerea

Botrytis cinerea is a very common mold fungus, which causes grey mold (also known as grey rot). It is known to affect over 200 different host plants, but its biggest impact is on fruit and produce: Globally, the annual damages from Botrytis are estimated to exceed ten billion dollars. And that does not include the losses in value for consumers, when they discover that the fruits and vegetables they bought a couple of days ago have been destroyed by grey mold.

Clonostachys rose

Clonostachys rosea is a very common, but otherwise unremarkable sac fungus of the Bionectriaceae family – it is indeed so unremarkable that it does not even have a colloquial name. Clonostachys is a parasite that in turn attacks parasitic organisms like bacteria, nematodes or other fungi – among the latter are Botrytis (grey mold) and Sclerotinia sclerotinorum (stem rot). Clonostachys does not damage the host plants, which makes this fungus a very promising natural crop protector.

Vector

Vector is a word with many meanings; biologists use it to describe an organism that is capable of carrying (“vectoring”) any type of pathogen – fungi, bacteria, or viruses, for example – to other organisms.

Written by: Jürgen Schönsten

Photos: Simon Räss

Illustration: Irene Servillo